Conveyor Belt"Ultimate Guide to Belt Conveyors: Applications, Types, and Benefits"

- Conveyor Belt is the most adaptable and straightforward material handling systems. They use two or more pulleys to move an endless loop belt.

- The loop then transfers a product from Point A to Point B on the belt. We use either fabric or rubber belts. Belt conveyors are widely used in the manufacturing and distribution industries.

- They are a material handling system that utilizes an endless loop belt driven by two or more pulleys to transport products from one point to another.

- The belt, typically made from fabric or rubber, moves items along the conveyor line, allowing for efficient transportation within manufacturing and distribution facilities.

- Belt conveyor systems are known for their versatility and simplicity, making them a popular choice for various industries.

- ENTRA creates conveyors ranging from 5′ to 102′ in length and width (6″ wide belts to 72″ wide belts and more).

- These conveyors are ideal for transporting both regular and irregular-shaped objects. Totes, packaged goods, and bulk boxes are among the most common items transported on these conveyors.

- Motorized belt conveyors are easy to install because of their simple design and construction. ENTRA can help you choose from the available models. There are both heavy-duty and light-duty models available.

- The possibilities are endless, but the majority are quite simple.

What are the most common applications for modular belting

Most Common Applications for Modular Belting

1-Food and Beverage Processing

2-Pharmaceutical and Medical Manufacturing

These belts are perfect for pharmaceuticals and medical sectors, where precision, hygiene, and strict standards are crucial. They effectively transport sensitive medical parts and products.

3- Packaging and Material Handling

Modular belts are excellent for packaging, sorting, and material handling. Their flexibility allows them to efficiently transport different package shapes and sizes, boosting productivity in warehouses and distribution centers.

4-Assembly Lines and Automotive Manufacturing

Modular belts are durable and customizable, making them ideal for assembly lines and automotive production. They efficiently handle different components and help streamline complex manufacturing processes.

5- Warehousing and Distribution

Modular belts are used in warehousing, tray merging, routing, and singulation systems because they can handle curves, inclines, and wide conveyor setups effectively.

6- Specialty Applications

They are used in drying, cooling, dewatering, and metal detection processes because they allow airflow and can be easily adapted to different setups due to their modular design.

In summary, modular belts are mainly used in food, pharmaceuticals, packaging, assembly, warehousing, and other specialized tasks that need hygiene, flexibility, and easy upkeep.

Our conveyor belt Designs

Rubber Belt

Hard Belt

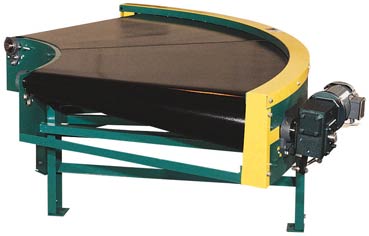

Curved

Inclined

Conveyor Belt Materials

Conveyor belts are manufactured using a wide range of materials, each selected for its unique properties and suitability for specific applications.

Common conveyor belt materials include rubber, PVC (polyvinyl chloride), polyurethane, metal, and fabric such as polyester or cotton.

Rubber belts are valued for their durability and flexibility, while PVC and polyurethane options are preferred in industries that require hygiene and chemical resistance, such as food processing and pharmaceuticals.

Metal belts, often made from stainless or carbon steel, are used in high-temperature or heavy-duty environments

Types of conveyor belt

- Slider Bed Belt Conveyor

- Roller Bed

- Incline Belt – Slider

- Incline Belt – Roller

- Troughed Belt Conveyor

- Trough Drum conveyor belt

Each type of conveyor belt system has its own unique features and benefits, making them suitable for different applications and industries

Belt Conveyors and conveyor belt for industrial and warehouse applications

Belt conveyors are widely used in industrial and warehouse applications for their efficiency and versatility in handling various materials. Some common uses of belt conveyors in these settings include:

1. Transporting Goods: ENTRA Belt conveyors move goods and materials from one location to another within a facility. These belt conveyors can transport items of varying sizes and weights, making them ideal for industrial applications where continuous movement of products is required.

2. Assembly Lines: Belt conveyors or (chain conveyors) often integrate into assembly lines to transport components or products between different stages of the manufacturing process. This helps streamline production and improve efficiency.

3. Loading and Unloading: ENTRA conveyors support the movement of goods between storage areas and vehicles in warehouses and distribution centers for loading and unloading trucks and containers.

4. Storage and Accumulation: ENTRA conveyors and Aluminum Conveyors serve for temporary storage or accumulation of goods before further processing or shipping. They allow for organized storage and controlled release of products as needed.

5. Heavy-Duty Applications: In industrial settings such as mining, construction, and bulk material handling, belt conveyors transport heavy and bulky materials over long distances. They are designed to withstand harsh conditions and heavy loads.

How Conveyor Belts Work

Conveyor belts are built to move materials smoothly and quickly inside a facility, whether over short or long distances.

They work with a continuous loop of belt that runs over two or more rotors or pulleys, powered by motors.

The belt’s friction with the rotors helps it move smoothly, carrying products or raw materials from one spot to another.

This system is essential in industries like mining and packaging, where moving large amounts of materials fast and safely is very important.

Conveyor Belts Including Modular Belting

Modern conveyor systems use modular belts made of interlocking plastic or metal segments.

These belts are lightweight, easy to clean, quick to assemble or repair, and suited for industries requiring high hygiene and little downtime.

They can operate in various temperatures and are ideal for bottling, packaging, and food processing.

An idler pulley is a key part of conveyor systems that supports and guides the conveyor belt.

It helps keep the belt properly tensioned and aligned, reducing wear and preventing sagging or misalignment.

There are different types of idler pulleys—such as equal idlers, picking idlers, self-aligning, and impact idlers—each suited for specific functions.

Choosing the right type and maintaining it properly are essential for the efficient and long-lasting operation of the conveyor system.

FAQ

What is modular belting?

Sure! Modular belting is a conveyor belt made of small, interlocking plastic pieces held together by hinge rods. This design makes it flexible, durable, and easy to maintain, so it’s useful in many industries and applications.

What are the main advantages of modular belts over traditional conveyor belts?

Modular belts are durable, easy to maintain (damaged parts can be replaced individually), resistant to chemicals and wear, and can handle curves and inclines. They are also hygienic and easy to clean, ideal for food and pharmaceutical industries.

Are modular belts easy to maintain?

Yes, modular belts are easy to maintain. If a part gets damaged, only that section needs replacing, which lowers downtime and costs compared to traditional belts that require full replacement.

Can modular belts be customized for specific applications?

Absolutely. Modular belts can be customized with accessories like flights and side guards, and arranged to handle complex layouts with curves and height changes.

How do modular belts improve safety and hygiene?

Modular belts are usually made from food-safe plastics with smooth, easy-to-clean surfaces to reduce contamination. They can also have safety features like anti-slip surfaces and rounded edges to prevent injuries.

Are modular belts cost-effective?

Although modular belts may cost more upfront, they save money over time through lower maintenance, less downtime, and better efficiency, making them a cost-effective choice for many industries.

In which industries are modular belts most commonly used?

Modular belts are most commonly used in food processing, packaging, automotive, logistics, and pharmaceutical industries because of their versatility, durability, and hygiene benefits.

How do you choose the right belt conveyor for your application?

Our business takes pride in offering top-notch services that cater to the specific needs of our clients. Moreover, we strive to build trust with potential clients by maintaining transparency, reliability, and open communication. Additionally, our track record of success and client satisfaction speaks for itself, showcasing our dedication to delivering high-quality results. Furthermore, we believe that our expertise, attention to detail, and personalized approach make us the perfect fit for those seeking exceptional service.

What safety precautions should be taken when working with belt conveyors?

Safety precautions when working with belt conveyors include wearing appropriate personal protective equipment, avoiding loose clothing or jewelry that can get caught in the conveyor, and following proper lockout/tagout procedures when performing maintenance.

How can you troubleshoot common issues with belt conveyors?

Common issues with belt conveyors include belt slippage, tracking problems, and material spillage. Troubleshooting involves checking for proper belt tension, alignment, and tracking, as well as inspecting components for damage or wear.

Other Products

Request a Quote for Belt Conveyors?

Are you ready to request a standard model? We have many conveyor belt systems for sale. Fast shipping is available on some ‘quick ship’ models.