Innovative Throughput Optimization: ENTRA’s Conveyor Assembly Matrix

November 22, 2024

ENTRA Belt Conveyors: A Comprehensive Guide

November 23, 2024Introduction

Conveyor systems are the backbone of modern industrial operations, revolutionizing material handling across multiple sectors. In Egypt and the Middle East, these technological marvels are transforming manufacturing, logistics, mining, and agriculture through advanced automation and efficiency.

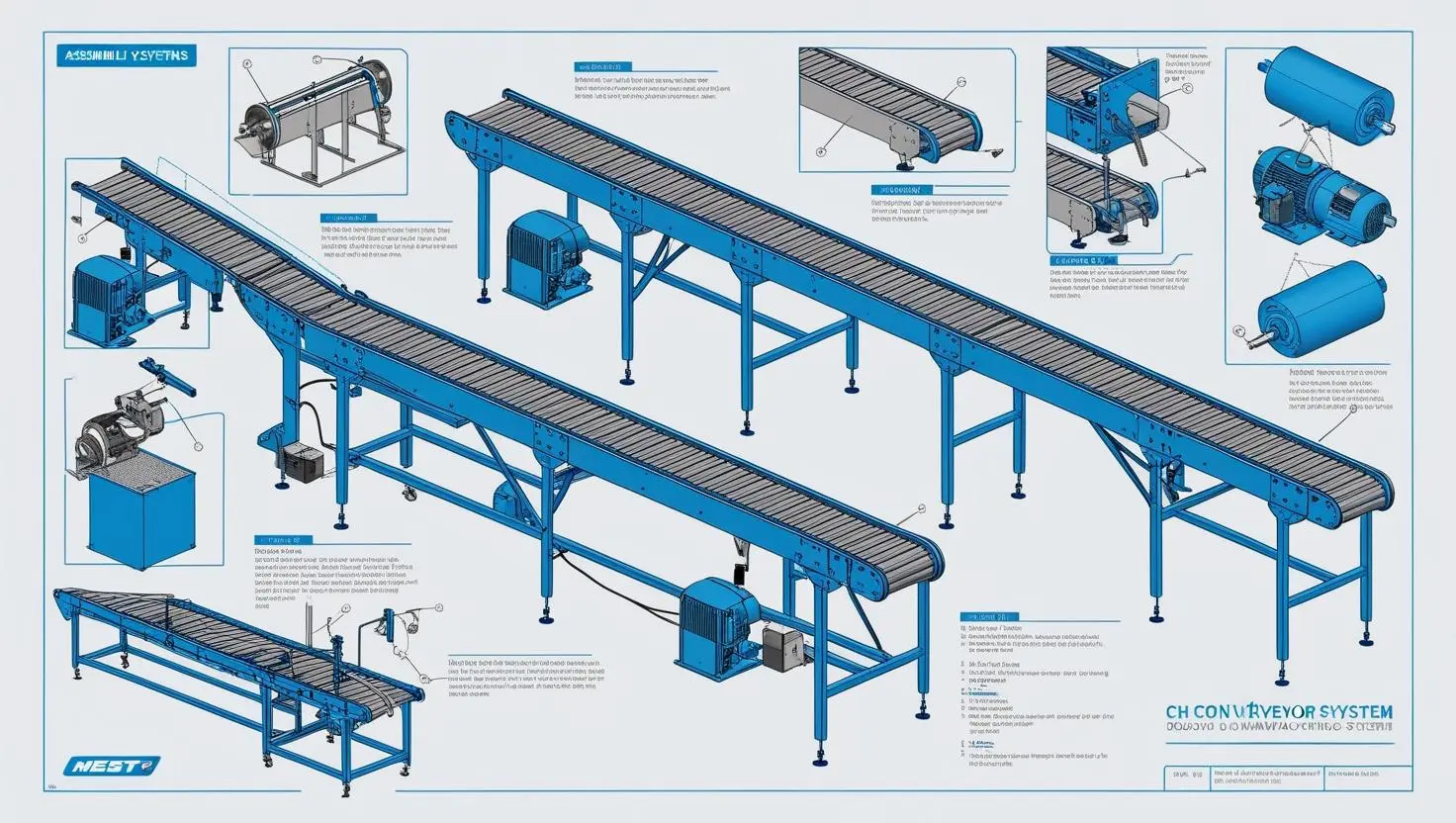

Understanding Conveyor Systems: The Fundamental Concept

A conveyor system is a mechanical handling equipment designed to transport materials, products, or goods from one point to another with minimal human intervention. The basic concept involves:

- A continuous moving belt or chain

- Powered by electric motors

- Designed to move items efficiently and consistently

- Reducing manual labor and increasing productivity

Types of Conveyor Systems

1. Belt Conveyors

- Most common type

- Flexible and versatile

- Used in multiple industries

- Can transport various materials and weights

2. Roller Conveyors

- Uses rollers to move items

- Ideal for heavy or rigid materials

- Commonly used in warehouses and packaging

3. Screw Conveyors

- Rotary mechanism for moving granular or liquid materials

- Classified into:

- Horizontal screw conveyors

- Inclined screw conveyors

- Vertical screw conveyors

4. Chain Conveyors

- Uses chains for movement

- Robust and durable

- Suitable for heavy industrial applications

5. Pneumatic Conveyors

- Uses air pressure to move materials

- Ideal for powders and fine granular substances

- Minimal contamination risk

Market Overview and Significance

Conveyor Belt Market Insights

- Global market size: Estimated at $7.6 billion in 2023

- Projected CAGR: 4.5% (2024-2030)

- Middle East region showing significant growth potential

Top Conveyor System Manufacturers

1. ENTRA Conveyor System and Automation Solutions

- Leading manufacturer in Egypt and the Middle East

- Specializes in custom industrial automation solutions

- Cutting-edge technology and local expertise

- Comprehensive range of conveyor systems

Other Global Leaders

Material Considerations for Conveyor Systems

Best Materials

- Stainless Steel

- Corrosion resistance

- Durability

- Hygienic properties

- High-Grade Polymers

- Lightweight

- Cost-effective

- Chemical resistance

- Specialized Composites

- Custom performance characteristics

- Industry-specific requirements

Designing a Conveyor System: Key Considerations

Design Process

- Assess material characteristics

- Determine load requirements

- Calculate transportation distance

- Choose appropriate conveyor type

- Design for specific environmental conditions

- Integrate safety mechanisms

Common Conveyor Sizes

- Small: 300mm width

- Medium: 600-900mm width

- Large: 1200-1500mm width

- Custom sizes available based on specific requirements

Control Systems

Conveyor Control Technologies

- PLC (Programmable Logic Controllers)

- SCADA Systems

- IoT-enabled monitoring

- Advanced automation interfaces

Alternative Material Transportation Methods

- Forklifts

- Overhead cranes

- Manual handling

- Automated guided vehicles (AGVs)

Where Conveyor Systems are Used

Key Industries

- Manufacturing

- Mining

- Food Processing

- Automotive

- Agriculture

- Logistics and Warehousing

- Pharmaceutical

- Packaging

Conclusion

Conveyor systems represent a critical technological infrastructure driving efficiency across industries. With ENTRA Conveyor System and Automation leading innovation in Egypt and the Middle East, the future of material handling looks promising, sustainable, and technologically advanced.

#ConveyorSystems,#IndustrialAutomation,#EgyptManufacturing,#MidEastTechnology, #MaterialHandling

Contact Information

ENTRA Conveyor System and Automation [Contact Details to be Inserted]