ENTRA Automation Solutions: Complete FAQ Guide

November 20, 2024

Innovative Throughput Optimization: ENTRA’s Conveyor Assembly Matrix

November 22, 2024Gravity Roller Conveyors: The Ultimate Guide to Efficient Material Handling Solutions in 2024

Discover how gravity roller conveyors revolutionize material handling. Learn about ENTRA’s cutting-edge conveyor systems, industry applications, and optimization strategies for your logistics.

Understanding Gravity Roller Conveyors: A Comprehensive Deep Dive

What Exactly Are Gravity Roller Conveyors?

Gravity roller conveyors are passive material handling systems that leverage gravitational force to transport goods efficiently across industrial environments. Unlike powered conveyor alternatives, these ingenious systems transform simple physics into a powerful logistics solution.

Key Performance Metrics

- Weight Capacity: 50-500 kg per roller

- Installation Flexibility: Adaptable to multiple industrial settings

- Energy Efficiency: Zero electrical power consumption

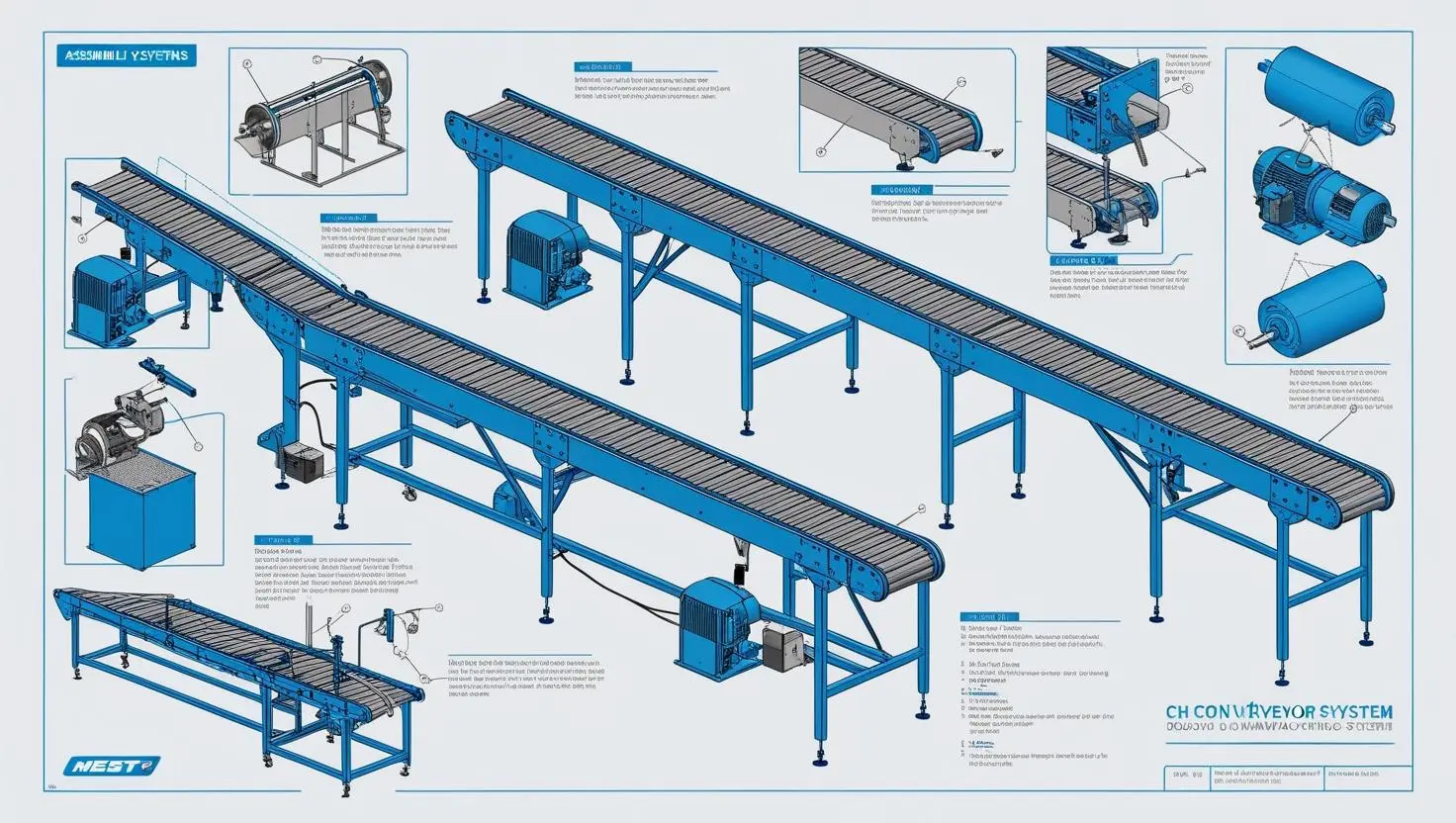

Technical Specifications and Design Considerations

Precision Engineering Components

- Advanced Roller Technology

- Material Composition: High-grade steel and aluminum alloys

- Bearing Quality: Precision-engineered for minimal friction

- Surface Treatment: Corrosion-resistant coatings

- Structural Integrity

- Frame Materials: Industrial-grade steel

- Modularity: Easy expansion and customization

- Load Distribution: Engineered for uniform weight management

ENTRA Conveyor System: Egypt’s Material Handling Innovation Leader

Why ENTRA Stands Out in Conveyor Automation

ENTRA Conveyor System isn’t just a manufacturer; they’re innovation architects in material handling technology. Their gravity roller conveyors represent the pinnacle of Egyptian industrial engineering, offering:

- Customized Solutions: Tailored to specific industry requirements

- Technological Innovation: Advanced engineering principles

- Reliability: Proven performance across diverse sectors

Industry-Specific Applications

- Warehousing

- Manufacturing

- Logistics

- Shipping and Receiving

- E-commerce Fulfillment Centers

Optimization Strategies for Maximum Efficiency

Performance Enhancement Techniques

- Slope Calculations

- Optimal Angle: 1-3 degrees

- Friction Coefficient Management

- Load-Specific Configurations

- Maintenance Protocols

- Predictive Maintenance Scheduling

- Component Wear Analysis

- Lubrication Best Practices

Comparative Advantages

Gravity Roller Conveyors vs. Powered Alternatives

| Feature | Gravity Roller Conveyors | Powered Conveyors |

|---|---|---|

| Energy Cost | $0 | High Electrical Consumption |

| Maintenance | Minimal | Complex |

| Installation Flexibility | Extremely High | Limited |

| Initial Investment | Low | Significantly Higher |

Frequently Asked Questions

Q1: How Do Gravity Roller Conveyors Work?

Gravity roller conveyors utilize the natural gravitational slope to move materials, eliminating the need for electrical power. Strategically angled rollers facilitate smooth, energy-efficient transportation.

Q2: What Industries Benefit Most from Gravity Roller Conveyors?

Warehousing, manufacturing, logistics, e-commerce, and shipping industries derive maximum value from these versatile material handling systems.

Q3: How Can I Determine the Right Conveyor Configuration?

Consult with experts like ENTRA Conveyor System to assess your specific operational requirements, product characteristics, and space constraints.

Q4: What Maintenance Is Required?

Regular inspection, roller alignment checks, bearing lubrication, and cleaning are essential for optimal performance and longevity.

Q5: Are Gravity Roller Conveyors Environmentally Friendly?

Yes! Zero electrical consumption and minimal material usage make them an eco-conscious material handling solution.

Conclusion: The Future of Efficient Material Handling

Gravity roller conveyors represent more than just a transportation mechanism—they’re a testament to intelligent, physics-driven engineering. By understanding their capabilities, businesses can transform logistical challenges into streamlined opportunities.

#GravityRollerConveyor#MaterialHandling#IndustrialLogistics#ConveyorSystems#LogisticsTechnology#WarehouseAutomation#IndustrialEngineering#ManufacturingTech#LogisticsSolutions

#IndustryInnovation#EngineeringDesign#TechInLogistics#ENTRAConveyor#EgyptianManufacturing#IndustrialEgypt#AfricanInnovation#ENTRATechnology#MadeInEgypt