Custom Gripper Conveyors for Your Unique Needs

Maximize Your Productivity with Custom Gripper Conveyors

Table of Contents

What are gripper conveyers?

In today’s dynamic industrial landscape, the seamless movement of materials plays a crucial role in enhancing operational efficiency and productivity. Gripper conveyors, with their innovative design and advanced functionality, have emerged as powerful tools for material handling in various industries. Let’s delve into the world of gripper conveyors and explore their benefits, applications, maintenance practices, and future trends in industrial material handling.

At ENTRA Electromechanical, we understand that each industrial facility has unique material handling needs. That’s why we offer custom gripper conveyors that are tailored to fit your specific requirements. Our team of experienced engineers will work with you to design a conveyor system that maximizes productivity and efficiency while minimizing costs. Whether you need a conveyor system for heavy-duty industrial use or lightweight applications, we’ve got you covered. Contact us today to learn more about our custom gripper conveyors.

Introduction to Gripper Conveyors

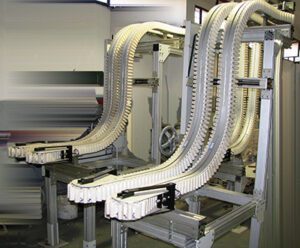

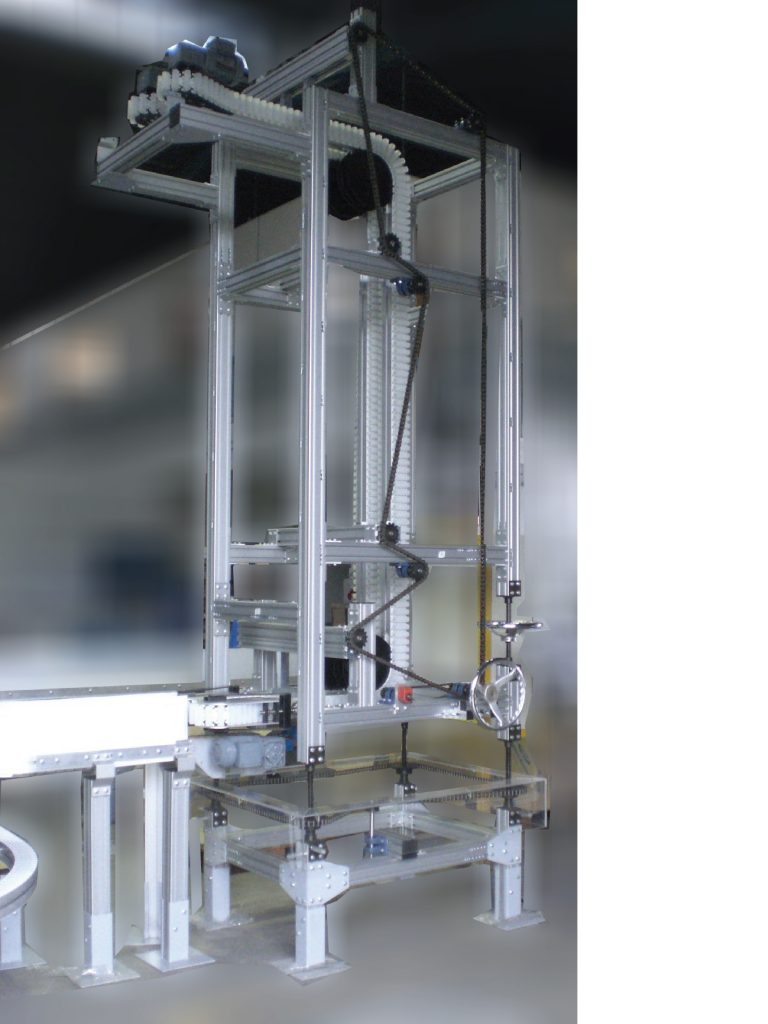

Bottle Gripper Conveyors are specialized systems designed to securely grip and transport materials along a conveyor belt. These conveyors are equipped with gripper mechanisms that ensure precise handling of a wide range of materials, making them ideal for industries that require efficient and reliable material transportation. In industrial settings, gripper conveyors have become indispensable for streamlining operations and improving overall productivity.

Benefits of Gripper Conveyors

One of the key advantages of gripper conveyors is their efficiency and precision in material handling. The gripper mechanism allows for secure gripping and release of materials, ensuring smooth movement along the conveyor system. Additionally, the automation capabilities of gripper conveyors enhance productivity by reducing manual labor and increasing throughput. This automation also leads to improved accuracy in material handling processes, resulting in cost savings and operational excellence.

Gripper Mechanism in Conveyors

The gripper mechanism in these conveyors is a critical component that enables the secure handling of materials. Grippers can be customized to meet specific requirements, providing versatility and adaptability to different applications. By securely gripping materials, gripper conveyors prevent slippage and ensure the smooth transfer of items along the conveyor belt. This level of precision and control is essential for industries that deal with delicate or irregularly shaped materials.

We do agree that businesses should prioritize conveyor system maintenance to avoid downtime or disruptions in their manufacturing, packaging, or delivery processes. You may, of course, analyze the operation of your system using a human-machine interface (HMI), which allows you to analyze and monitor historical and real-time data.

Ahmed Abdel Ghaffar

Applications of Gripper Conveyors

- Aero-mechanical

- Automotive

- Belt conveyor

- Chain

- Chain-driven live roller

- Flexible

- Gravity

- Pharmaceutical

- Plastic belt

- Pneumatic

- Screw or auger conveyor

- Vibrating

Choosing the Right Gripper Conveyor

Maintenance of Gripper Conveyors

Proper maintenance is crucial for the optimal performance and longevity of gripper conveyors. Regular servicing and inspection of the conveyor system can help prevent breakdowns and minimize downtime. Following maintenance guidelines provided by the manufacturer is essential to ensure the smooth operation of the conveyor system. Additionally, implementing safety measures and conducting regular safety audits can create a secure working environment for employees.

FAQ

What industries can benefit from using gripper conveyors?

Gripper conveyors are versatile systems that find applications in industries such as automotive, food and beverage, pharmaceuticals, and more, ENTRA Offers wide range of conveyors to serve this area.

How can businesses choose the right gripper conveyor for their operations?

Businesses should consider factors such as material handling requirements, customization options, and manufacturer reputation when selecting a gripper conveyor.

at ENTRA we will guide you to the best solution for your manufacturing needs.

What are some common issues that may arise with gripper conveyors?

Common issues with gripper conveyors include jammed materials, misaligned grippers, and motor malfunctions that can be addressed through troubleshooting techniques.

at ENTRA We ensure that no such issues affects your system with a proper guide and maintenance all is fixed.

How can businesses maximize the efficiency of gripper conveyors?

implementing operational best practices, regular maintenance routines, and employee training on safe operating procedures, businesses can optimize the efficiency of gripper conveyors.

What are some best practices for installing gripper conveyors in an industrial facility?

Best practices for installing gripper conveyors include following a step-by-step installation guide, ensuring proper alignment and calibration, and conducting regular inspections to maintain optimal performance.

What are the future trends in gripper conveyor technology?

Future trends in gripper conveyor technology may include advancements in automation, connectivity, and efficiency to further improve the performance and capabilities of these systems.

What are the environmental benefits of using gripper conveyors?

Gripper conveyors contribute to sustainability in industrial operations by streamlining material handling processes, reducing waste, and minimizing energy consumption through energy-efficient design features.

How can businesses conduct a cost analysis for integrating gripper conveyors into their operations?

Businesses can evaluate the return on investment and potential cost savings by comparing the initial investment with the long-term benefits of improved efficiency, productivity, and operational performance.

Are there any specific safety considerations when using gripper conveyors?

Safety considerations when using gripper conveyors include implementing safety protocols, providing employee training on safe operating procedures, and ensuring a secure working environment for employees to prevent accidents and injuries.

Can gripper conveyors be customized to suit specific material handling needs?

Yes, gripper conveyors offer a range of customization options to tailor solutions to specific material handling requirements, including custom gripper mechanisms, conveyor belts, and control systems.

Do You Need a Conveyor System?

If you need a conveyor system for the logistics sector, food industry, or commercial purposes, ENTRA is delighted to assist.

Contact us today to discuss your requirements and create a custom solution for your organization.Read more about other categories