Hydraulic and Electric Lift Tables

Hydraulic and Electric Lift Tables: The Complete Guide for 2024

`Hydraulic and Electric Lift Tables have become an indispensable tool for material handling and workplace ergonomics. This comprehensive guide explores the two main types of lift tables – hydraulic and electric – helping you understand their features, benefits, and ideal applications. Whether you’re managing a warehouse, optimizing a production line, or seeking efficient material handling solutions, this guide will provide valuable insights into choosing and utilizing the right lift table for your needs.

UnderstandingHydraulic and Electric Lift Tables Basics

Lift tables are versatile platforms designed to raise and lower loads to optimal working heights. These essential pieces of equipment enhance workplace safety, improve efficiency, and reduce the risk of workplace injuries. Before diving into specific types, it’s crucial to understand the fundamental purpose of lift tables in various industrial applications.

Key Benefits of Lift Tables:

- Improved workplace ergonomics

- Reduced risk of workplace injuries

- Enhanced productivity

- Versatile material handling capabilities

- Customizable solutions for specific applications

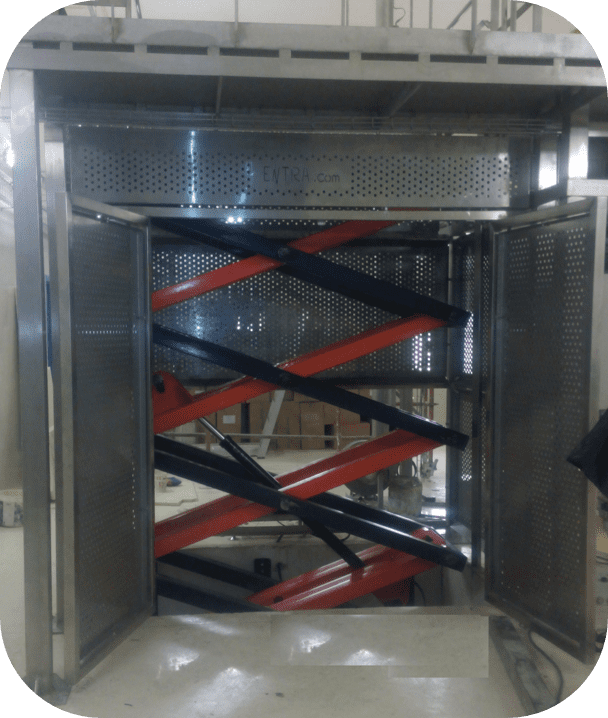

Hydraulic Lift Tables: Power and Reliability

What Are Hydraulic Lift Tables?

Hydraulic lift tables utilize fluid power systems to raise and lower loads. These robust platforms rely on hydraulic cylinders and pumps to generate the force necessary for lifting heavy loads. The hydraulic system provides smooth, controlled movement and exceptional stability.

Key Features of Hydraulic Scissors Lift Tables:

- Robust Construction

- Heavy-duty steel construction

- Reinforced scissor mechanisms

- Durable hydraulic components

- Lifting Capacity

- Standard capacities from 500 to 6000 pounds

- Custom solutions available for heavier loads

- Multiple scissor configurations for extended lift heights

- Safety Features

- Maintenance bars for secure servicing

- Pressure relief valves

- Emergency stop controls

- Anti-slip surfaces

Key Features of Hydraulic Scissors Lift Tables:

- Robust Construction

- Heavy-duty steel construction

- Reinforced scissor mechanisms

- Durable hydraulic components

- Lifting Capacity

- Standard capacities from 500 to 6000 pounds

- Custom solutions available for heavier loads

- Multiple scissor configurations for extended lift heights

- Safety Features

- Maintenance bars for secure servicing

- Pressure relief valves

- Emergency stop controls

- Anti-slip surfaces

Advantages of Hydraulic Systems:

- Consistent performance under heavy loads

- Lower initial investment compared to electric alternatives

- Simple maintenance requirements

- Reliable operation in various environments

- Extended service life with proper maintenance

Electric Lift Tables: Precision and Convenience

Understanding Electric Lift Tables

Electric lift tables employ motorized systems to provide precise, powered lifting capabilities. These modern solutions offer enhanced control and convenience, making them ideal for applications requiring frequent height adjustments or specific positioning requirements.

Essential Features of Electric Lift Tables:

- Power Systems

- Battery-powered options for mobility

- 12V and 24V systems available

- Rechargeable power sources

- AC-powered models for stationary applications

- Control Systems

- Programmable height settings

- Remote control options

- Digital displays

- Position memory functions

- Safety and Convenience

- Automatic shut-off systems

- Overload protection

- Emergency stop buttons

- Low battery indicators

Benefits of Electric Systems:

- Precise height control

- Quieter operation

- Clean operation (no hydraulic fluid)

- Reduced maintenance requirements

- Energy-efficient operation

Choosing Between Hydraulic and Electric Lift Tables

Factors to Consider:

- Application Requirements

- Load capacity needs

- Frequency of use

- Environmental conditions

- Power availability

- Space constraints

- Cost Considerations

- Initial investment

- Operating costs

- Maintenance expenses

- Expected service life

- Return on investment

- Operational Factors

- Ease of use

- Speed requirements

- Precision needs

- Mobility requirements

- Safety considerations

Advanced Features and Customization Options

Popular Modifications:

- Platform Configurations

- Rotating tops

- Tilting surfaces

- Extended platforms

- Custom dimensions

- Special coatings

- Mobility Options

- Caster wheels

- Fixed positions

- Towable designs

- Guide rails

- Positioning systems

- Control Enhancements

- Remote operations

- Automated cycling

- Integration capabilities

- Safety interlocks

- Position sensors

Maintenance and Care

Regular Maintenance Tasks:

- Hydraulic Systems

- Fluid level checks

- Seal inspections

- Cylinder maintenance

- Pressure testing

- Lubrication requirements

- Electric Systems

- Battery maintenance

- Motor inspections

- Control system checks

- Wire maintenance

- Charging system care

Safety Considerations and Best Practices

Essential Safety Guidelines:

- Operation Safety

- Load capacity adherence

- Proper load positioning

- Operator training

- Emergency procedures

- Regular inspections

- Workplace Integration

- Traffic management

- Space requirements

- Power access

- Safety zones

- Emergency access

Industry Applications for Hydraulic and Electric Lift Tables,

Common Use Cases:

- Manufacturing

- Assembly lines

- Work positioning

- Material transfer

- Production support

- Quality control

- Warehousing

- Order picking

- Pallet handling

- Loading/unloading

- Storage access

- Cross-docking

- Retail

- Stock management

- Display setup

- Inventory handling

- Customer service

- Store maintenanc