دليلك الشامل لاختيار مصنع سيور ناقلة في مصر: حلول متكاملة للصناعة المصرية

November 19, 2024Industrial Conveyor efficiency and productivity are paramount to success. At the heart of this operational excellence lies a crucial piece of technology: industrial conveyor systems. These sophisticated material handling solutions have revolutionized how businesses move products, materials, and components throughout their facilities. Let’s delve into why these systems have become indispensable in modern manufacturing and logistics operations.

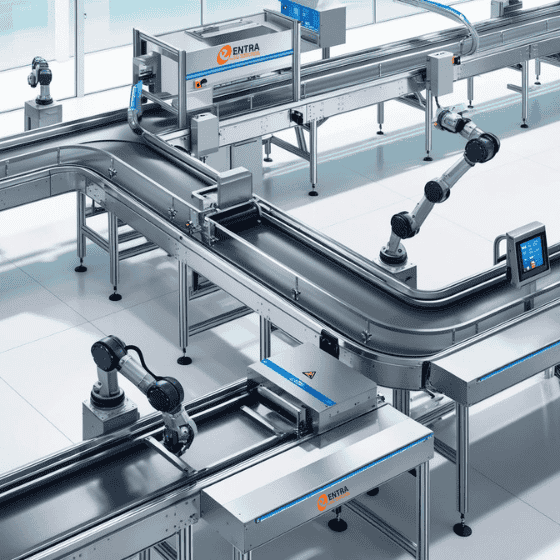

Understanding Industrial Conveyor Systems

Industrial conveyor systems are engineered material handling solutions designed to transport goods and materials efficiently across various distances within a facility. These systems come in multiple configurations, each tailored to specific industry needs and applications.

Key Components of Industrial Conveyor Systems

- Drive Units

- Motors and gearboxes

- Power transmission systems

- Speed controllers

- Emergency stop mechanisms

- Conveying Media

- Belts

- Rollers

- Chains

- Modular platforms

- Support Structure

- Frames and supports

- Guide rails

- Safety guards

- Mounting brackets

Benefits of Modern Industrial Conveyor Systems

Enhanced Efficiency

Modern industrial conveyor systems significantly improve operational efficiency through:

- Continuous material flow

- Reduced manual handling

- Optimized space utilization

- Increased throughput capacity

Improved Safety

Safety improvements include:

- Reduced workplace injuries

- Minimized manual lifting requirements

- Enhanced ergonomics

- Controlled material movement

Cost-Effective Operations

Financial benefits encompass:

- Lower labor costs

- Reduced product damage

- Improved inventory control

- Enhanced production scheduling

Applications Across Industries

Industrial conveyor systems find crucial applications in various sectors:

Manufacturing

- Assembly line operations

- Component transportation

- Packaging lines

- Quality control stations

Warehousing

- Order fulfillment

- Cross-docking operations

- Storage systems integration

- Loading/unloading operations

Food Processing

- Hygiene-compliant systems

- Temperature-controlled zones

- Clean-room environments

- Quality inspection points

Innovation in Modern Conveyor Systems

Today’s industrial conveyor systems incorporate cutting-edge technologies:

Automation Integration

- Smart controls

- Programmable logic controllers

- Real-time monitoring

- Predictive maintenance systems

Energy Efficiency

- Variable speed drives

- Energy-recuperation systems

- Smart power management

- Eco-friendly materials

Customization Options

- Modular designs

- Scalable solutions

- Industry-specific adaptations

- Custom configurations

Selecting the Right Industrial Conveyor System

When choosing an industrial conveyor system, consider:

Operational Requirements

- Material characteristics

- Production volume

- Space constraints

- Environmental conditions

Technical Specifications

- Speed requirements

- Load capacity

- Control systems

- Maintenance needs

Future Scalability

- Expansion possibilities

- Technology integration

- Upgrade potential

- System flexibility

Maintenance and Longevity

To ensure optimal performance and longevity:

Regular Maintenance

- Scheduled inspections

- Component replacement

- Lubrication programs

- Performance monitoring

Preventive Care

- Early problem detection

- Wear monitoring

- Alignment checks

- Safety inspections

Conclusion

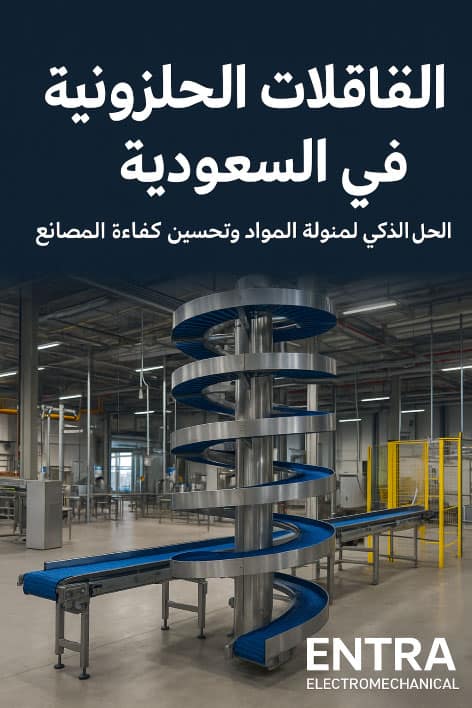

Industrial conveyor systems represent a crucial investment in operational efficiency and productivity. By understanding their capabilities, applications, and maintenance requirements, businesses can make informed decisions about implementing these essential material handling solutions. As technology continues to evolve, these systems will become even more integral to modern industrial operations.

Whether you’re considering upgrading existing systems or implementing new solutions, ENTRA conveyor systems offer proven benefits that can transform your operations. The key lies in selecting the right system for your specific needs and maintaining it properly to ensure long-term success.