Introduction to Screw Conveyors in Egypt

Screw conveyors have become an integral part of Egypt’s industrial landscape, playing a crucial role in material handling across various sectors.

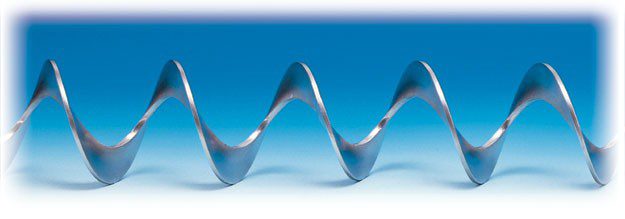

These efficient mechanical devices, consisting of a rotating helical screw blade within a tube, have been utilized in Egypt since the early industrial era, with significant modernization occurring over the past few decades.

The Egyptian market for screw conveyors has witnessed remarkable growth in recent years, driven by expanding agriculture, cement production, and manufacturing sectors.

As Egypt continues its industrial development under Vision 2030, the demand for efficient material handling solutions has positioned screw conveyors as essential equipment for businesses across the country, from Alexandria’s manufacturing zones to the agricultural regions of the Nile Delta.

Types of Screw Conveyors Available in Egypt

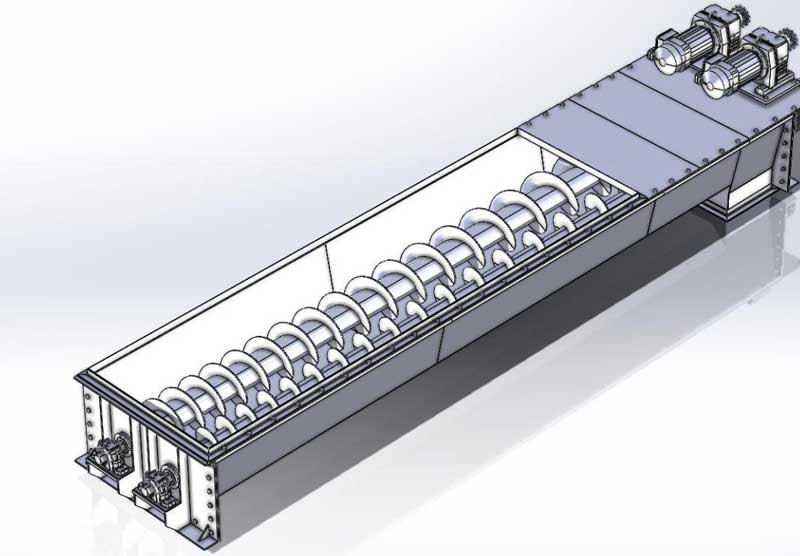

Horizontal Screw Conveyors

Horizontal screw conveyors are the most common type found in Egyptian facilities, particularly in cement plants and grain processing facilities. These conveyors excel at moving materials across level surfaces, making them ideal for production lines in Egypt’s growing manufacturing sector.

Vertical Screw Conveyors

With limited floor space in many urban Egyptian industrial zones, vertical screw conveyors (also known as screw lifts) provide an excellent solution for moving materials between different levels of a facility. These are commonly used in Cairo’s food processing plants and Alexandria’s pharmaceutical industries.

Inclined Screw Conveyors

These specialized conveyors operate at angles between horizontal and vertical positions, offering flexibility for facilities with unique spatial constraints. Many Egyptian quarries and mining operations utilize inclined screw conveyors to transport materials from excavation sites to processing areas.

Material Options for Egyptian Environments

- Stainless Steel: Preferred for food processing and pharmaceutical applications, particularly important in Egypt’s growing food export industry

- Carbon Steel: Common in cement production and mining operations throughout Upper Egypt

- Specialized Coatings: Many conveyors in Egypt feature special coatings to withstand the country’s hot, dusty conditions and prevent corrosion in coastal areas

Applications in Egyptian Industries

Agriculture Sector

Egypt’s agricultural industry, centered around the fertile Nile Delta, relies heavily on screw conveyors for grain handling. These conveyors efficiently move wheat, corn, and rice from receiving areas to storage silos throughout the country’s agricultural infrastructure. The ability to handle delicate grains with minimal damage makes screw conveyors particularly valuable to Egypt’s food security initiatives.

Cement Production

With Egypt’s construction boom driving demand for building materials, cement plants across the country utilize screw conveyors to transport raw materials and finished cement. The ability to move abrasive materials reliably in dusty conditions makes these conveyors essential to Egypt’s cement industry, which serves both domestic construction and export markets.

Chemical Processing

Egypt’s chemical industry, concentrated in industrial zones like 6th of October City and Borg El Arab, uses screw conveyors to transport various powders, granules, and solid chemicals. The enclosed design of these conveyors provides safety benefits when handling potentially hazardous materials, an important consideration under Egypt’s industrial safety regulations.

Mining Operations

From the Eastern Desert to Sinai, Egypt’s mining operations rely on heavy-duty screw conveyors to transport extracted minerals and processing byproducts. These conveyors are specially designed to handle abrasive materials under the harsh conditions typical of Egypt’s mining regions.

Wastewater Treatment

As Egypt invests in modern wastewater infrastructure, treatment facilities increasingly employ screw conveyors for sludge handling. These specialized conveyors transport dewatered sludge and solid waste, contributing to environmental improvements in communities along the Nile.

Selecting the Right Screw Conveyor for Egyptian Operations

Climate Considerations

Egypt’s climate presents unique challenges for industrial equipment. When selecting screw conveyors, businesses must consider:

- Heat resistance for equipment operating in Upper Egypt, where temperatures regularly exceed 40°C

- Dust protection mechanisms for installations in desert-adjacent facilities

- Corrosion resistance for operations near the Mediterranean and Red Sea coasts

- Water resistance features for agricultural applications during irrigation seasons

Material Handling Requirements

Different industries have specific requirements based on the materials being transported: Bulk Density: Affects the power requirements and screw design Abrasiveness: Determines material selection and wear protection needed Moisture Content: Influences trough design and potential for material buildup Flow Properties: Determines pitch selection and special features neededSizing and Capacity Calculations

Proper sizing is critical for efficient operation. Egyptian facilities should consider:

- Required throughput capacity (typically measured in cubic meters per hour)

- Available space constraints, particularly in older industrial facilities

- Power availability and efficiency requirements

- Integration with existing production lines

Leading Screw Conveyor Manufacturers and Suppliers in Egypt

Local Egyptian Manufacturers

Several Egyptian companies have developed expertise in manufacturing screw conveyors suited to local conditions:

- ENTRA Conveyor System: Based in Abu Rawash, specializing in custom solutions for all industries

Comparative Advantages

Local manufacturers typically offer:

- Faster response times for service and parts

- Designs adapted to Egyptian operating conditions

- More competitive pricing for standard models

- Better understanding of local regulatory requirements

Installation and Maintenance Best Practices

Installation Considerations for Egyptian Facilities

- Foundation Requirements: Particularly important in areas with unstable soil conditions

- Access for Maintenance: Ensuring adequate space in often crowded Egyptian industrial layouts

- Integration with Existing Systems: Compatible with locally used control systems

- Dust Containment: Critical in Egypt’s often dusty industrial environments

Key Features and Specifications

Screw Conveyor Capacity

The capacity of a screw conveyor is determined by the size and speed of the screw. For operations that require moving large amounts of material quickly, a higher capacity conveyor is necessary. Understanding the specific requirements of your process is crucial in selecting the right conveyor.

Screw Conveyor Efficiency

Efficiency in screw conveyors can be achieved by optimizing the design and operational parameters. This includes selecting the appropriate screw diameter, pitch, and speed. An efficient conveyor reduces operational costs and increases productivity.

Screw Conveyor Speed

The speed at which the screw rotates affects the conveyor’s throughput. By adjusting the speed, operators can control the flow rate of the material being transported. This flexibility allows for better management of the production process.

Industry-Specific Applications

Screw Conveyor for Agriculture

In agriculture, screw conveyors are used to transport grains, seeds, and other bulk materials. They are essential for efficient farm operations, from planting to harvesting and storage.

Screw Conveyor for Mining

Mining operations rely heavily on screw conveyors for moving extracted materials like ore and coal. These conveyors are built to withstand harsh conditions and handle abrasive materials.

Screw conveyor for Food processing

Screw conveyors are commonly used in the food industry to transport ingredients, powders, and other materials during the production process. They are often used to mix, blend, and distribute ingredients for baking, mixing, and packaging.

Best Engineering Services

Enhancing Screw Conveyor Performance

Screw conveyors are indispensable in many industries, offering flexible and efficient solutions for material handling. By understanding their features, capabilities, and maintenance needs, you can ensure that your operations run smoothly and efficiently.

FAQ

What are the main advantages of screw conveyors for Egyptian industries?

Screw conveyors offer enclosed operation (reducing dust problems common in Egypt’s environment), relatively low energy consumption, simple maintenance requirements, and versatility across different materials and industries. Their sealed design is particularly valuable in Egypt’s dusty conditions, preventing material contamination and reducing workplace hazards. Additionally, their compact footprint makes them ideal for the often space-constrained industrial facilities found throughout Egypt.

How do screw conveyors compare to other conveyor types in Egyptian conditions?

Compared to belt conveyors, screw conveyors offer better dust containment and require less space—important factors in many Egyptian facilities. They handle inclines better than roller conveyors and provide more gentle material handling than pneumatic systems, which is critical for Egypt’s grain processing sector. In Egypt’s cement industry, screw conveyors outperform other types when dealing with the extremely abrasive materials common in local production. For agricultural applications in the Delta region, their enclosed design protects valuable grain from contamination and weather exposure.

What are the typical maintenance challenges in Egypt?

The most common maintenance issues include bearing failures due to dust infiltration, accelerated wear in abrasive applications, and drive system problems related to power fluctuations still common in some industrial areas. Local service providers have developed specialized approaches to address these Egypt-specific challenges. In particular, many Egyptian facilities install enhanced sealing systems and use specialized hardened steel for screw flights to extend service life in the country’s harsh environmental conditions. Maintenance schedules are typically accelerated during khamsin season when dust levels are extraordinarily high.

How do regulatory requirements affect screw conveyor installations in Egypt?

Egyptian industrial facilities must comply with both general industrial safety regulations and industry-specific standards. Food processing applications must meet particularly stringent requirements under Egypt’s food safety regulations. All equipment installations require industrial safety certifications from the Ministry of Industry. Since 2023, new regulations require dust containment validation for all new conveyor installations in Egyptian industrial zones. Additionally, any equipment used in food production must obtain certification from the Egyptian Food Safety Authority before commissioning.

What capacity ranges are available for screw conveyors in the Egyptian market?

Screw conveyors available in Egypt typically range from small units handling 1-2 cubic meters per hour for specialty applications up to large industrial systems capable of moving 200+ cubic meters per hour in mining and cement operations. The most commonly installed systems in Egyptian manufacturing fall within the 15-50 cubic meters per hour range. Egyptian suppliers typically stock components for these mid-range systems, while very large or very small systems may require longer lead times.

How long do screw conveyors typically last in Egyptian operating environments?

With proper maintenance, industrial screw conveyors in Egypt typically provide 10-15 years of reliable service before requiring major overhauls. However, this varies significantly by application. In particularly abrasive applications like cement production, flight replacement may be needed every 3-5 years. Agricultural applications generally see longer component life due to the less abrasive nature of the materials being handled. Coastal installations near Alexandria or Port Said often require specialized corrosion-resistant materials to achieve comparable service life due to salt air exposure.

Can existing conveyor systems in Egyptian facilities be upgraded rather than replaced?

Yes, many Egyptian facilities successfully upgrade existing screw conveyor systems rather than completely replacing them. Common upgrades include replacing carbon steel flights with hardened steel or adding modern control systems to older mechanical drives. Local engineering firms specialize in these retrofits, which typically cost 30-40% less than complete system replacement. The Industrial Modernization Centre offers partial funding for such upgrades as part of Egypt’s industrial efficiency initiatives.

How do screw conveyors perform during Egypt's frequent power fluctuations?

Power stability remains a challenge in some Egyptian industrial areas. Modern screw conveyor systems incorporate protective features like soft starters, phase protection relays, and in some cases, UPS backup for control systems to prevent damage during power fluctuations. Many larger Egyptian facilities have installed variable frequency drives (VFDs) that both protect equipment from power issues and enable energy-efficient operation by matching conveyor speed to production requirements.

Are there Egyptian-specific design considerations for screw conveyors?

Yes, several design elements are particularly important for Egyptian operations:

- Enhanced dust sealing to deal with Egypt’s often dusty conditions

- High-temperature bearings for operations in Upper Egypt

- Specialized coatings for coastal installations near Alexandria or Port Said

- Heavy-duty designs for the particularly abrasive limestone used in Egyptian cement production

- Cooling systems for drives operating in Egypt’s hot climate, particularly in summer months

- Stainless steel construction for food applications to meet strict Egyptian food safety requirements

Related Products

Contact Us

We would love to speak with you.

Feel free to reach out using the below details.