Spiral Conveyor:Revolutionizing Workflow The Power booster in Factory Operations"

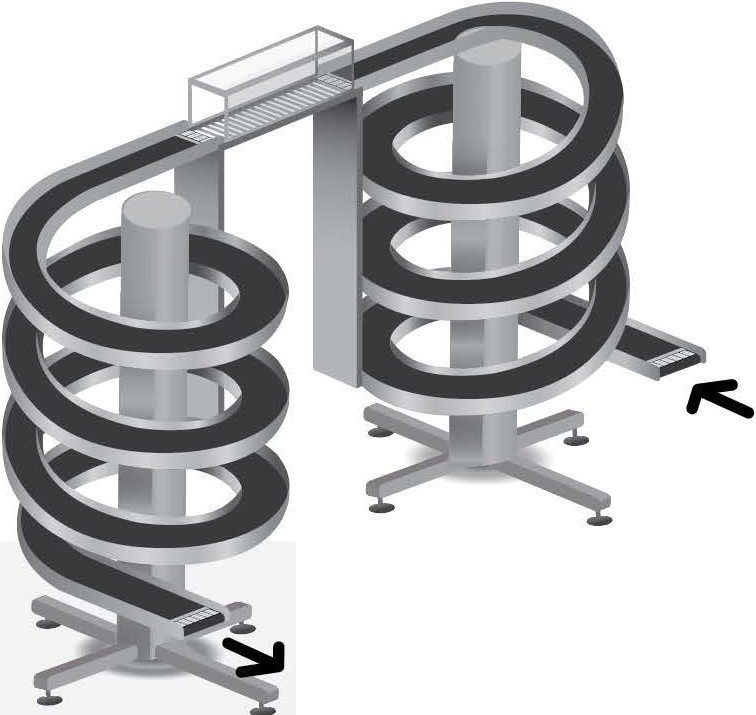

A spiral conveyor is a type of conveyor system that uses a helical path to transport materials or products from one level to another. The spiral design allows for continuous flow of materials without the need for transfers or changes in direction.

Spiral conveyors are commonly used in manufacturing and distribution facilities to move items vertically or horizontally in a compact and efficient manner. They are often used in applications where space is limited and a high throughput is required.

Maximizing Efficiency with Spiral Conveyors

Additionally, spiral conveyors are highly efficient and can handle a wide range of materials, making them versatile for various industries.

Furthermore, their compact design allows for easy integration into existing production lines without the need for major renovations.

In conclusion, spiral conveyors are a cost-effective and practical solution for factories looking to optimize their operations and increase productivity.

The Benefits of Spiral Conveyors for Factory Owners

Factory owners stand to benefit greatly from incorporating spiral conveyors into their operations.

These systems offer a range of advantages, from space-saving benefits to improved material handling capabilities.

By using spiral conveyors, factory owners can reduce the need for multiple conveyors or complex transfer systems, simplifying their operations and saving valuable floor space.

Additionally, spiral conveyors can help streamline workflow, reducing the risk of bottlenecks and delays in production.

Optimizing Workflow with Spiral Conveyors

One of the key advantages of spiral conveyors is their ability to optimize workflow in a factory setting.

By providing a continuous flow of materials, spiral conveyors can help ensure a smooth and efficient production process. This can lead to increased productivity, reduced downtime, and ultimately, improved profitability for factory owners.

With the ability to transport materials both up and down, spiral conveyors offer a versatile solution for factories looking to enhance their material handling capabilities.

Choosing the Right Spiral Conveyor for Your Factory

ENTRA Offers a wide range of Spiral Conveyors

When selecting a spiral conveyor system for a factory, there are several factors to consider.

It is important to assess the specific needs and requirements of the factory as well as the available space and budget constraints.

Additionally, factory owners should work closely with a reputable spiral conveyor manufacturer like ENTRA to ensure they choose a system that is tailored to their unique needs. By selecting the right spiral conveyor for their factory, owners can unlock the full potential of this innovative technology and reap the benefits of improved efficiency and productivity.

ENTRA and MODU Systems offers a wide range of conveyor system suitable for any production line

streamline your workflow with ENTRA's Spiral Conveyors

Spiral conveyors are known for their space-saving advantages, making them an ideal choice for warehouse owners looking to optimize their storage capacity. By utilizing vertical space effectively

Installation of Spiral Conveyors

Proper installation and regular maintenance are essential for the optimal performance of spiral conveyors. Following manufacturer guidelines during the setup process and implementing routine maintenance practices can help prolong the lifespan of the system and prevent operational issues.

Maintenance of Spiral Conveyors

By investing time and effort into installation and maintenance, factory owners can ensure the smooth operation of their spiral conveyors.

FAQ

Are spiral conveyors suitable for all types of materials in a factory setting?

Spiral conveyors are versatile systems that can handle a wide range of materials commonly found in factory settings, including boxes, cartons, totes, bags, and loose items. However, the suitability of a spiral conveyor for specific materials depends on factors such as size, weight, shape, and fragility. It is essential to consult with the manufacturer or supplier to determine the compatibility of the spiral conveyor with the materials to be transported.

How can factory owners ensure the proper maintenance of spiral conveyor systems?

Proper maintenance of spiral conveyor systems is crucial to ensure optimal performance and longevity. Factory owners can follow manufacturer-recommended maintenance schedules, conduct regular inspections, clean the system as needed, check for wear and tear on components, and address any issues promptly. Training staff on proper operation and maintenance procedures can also help prevent breakdowns and extend the lifespan of the spiral conveyor system.

What are some common challenges associated with installing spiral conveyors in manufacturing facilities?

Some common challenges associated with installing spiral conveyors in manufacturing facilities include space constraints, integration with existing conveyor systems, alignment with production processes, electrical and mechanical requirements, and safety considerations. Overcoming these challenges may require careful planning, collaboration with experienced suppliers, and customization of the spiral conveyor system to fit the specific needs of the facility.

Can spiral conveyors be customized to meet specific factory requirements?

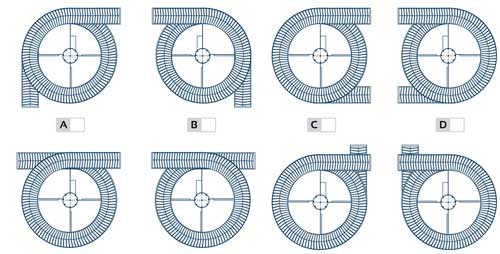

Yes, spiral conveyors can be customized to meet specific factory requirements, such as size, capacity, speed, configuration, and material handling needs. Manufacturers often offer customization options, including different belt types, drive systems, controls, and accessories, to tailor the spiral conveyor system to the unique specifications of the factory. Working closely with the manufacturer during the design and planning stages can help ensure that the customized spiral conveyor meets the desired requirements.

What role do spiral conveyors play in enhancing overall workflow efficiency in factories?

Spiral conveyors play a critical role in enhancing overall workflow efficiency in factories by optimizing material flow, reducing manual handling, increasing storage capacity, minimizing downtime, and improving order fulfillment processes. With their space-saving advantages and vertical transport capabilities, spiral conveyors enable factories to streamline operations, maximize productivity, and achieve cost savings. Integrating spiral conveyors into factory layouts can lead to a more efficient and organized workflow, ultimately enhancing the overall performance of the facility.

How do spiral conveyors contribute to improving safety in factory environments?

Spiral conveyors contribute to improving safety in factory environments by reducing the need for manual handling, minimizing the risk of injuries associated with lifting and carrying heavy items, and enhancing the overall ergonomics of material handling processes. By automating the transport of materials between different levels of the factory, spiral conveyors help create a safer working environment for employees, reduce the likelihood of accidents, and promote compliance with safety regulations. Implementing safety features such as guardrails, emergency stop buttons, and sensors can further enhance the safety of spiral conveyor systems in factory settings.

Contact Us

We would love to speak with you.

Feel free to reach out using the below details.