- Have any questions?

- +201100834634

- entra@entra-eg.com

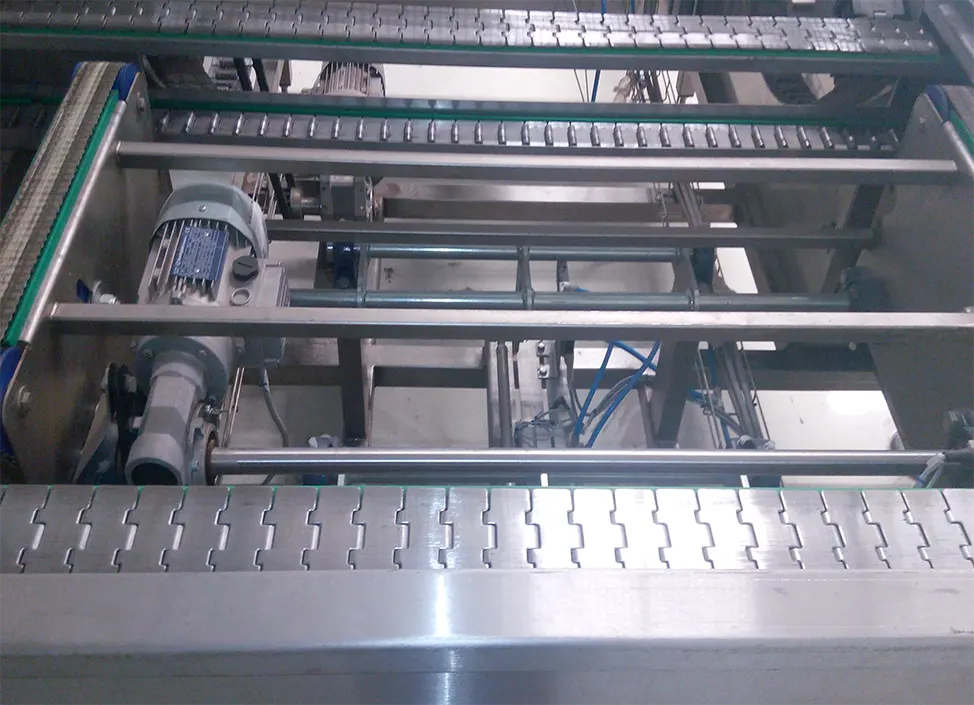

Stainless Steel Conveyors

Efficient Design

What are the uses of stainless steel conveyors?

Stainless-steel-conveyors are commonly used in various industries for transporting products or materials along a production line or assembly process. They are preferred for their durability, resistance to corrosion, and ease of cleaning. Some common applications of stainless steel conveyors include:

1. Food and beverage industry: Used for conveying food products, beverages, and packaging materials in food processing plants, bottling facilities, and packaging lines.

2. Pharmaceutical industry: used for transporting medications, medical devices, and other pharmaceutical products in manufacturing and packaging operations.

3. Automotive industry: Used for moving components, parts, and products during manufacturing, assembly, and finishing processes.

4. Cosmetics and personal care industry: Used for conveying cosmetics, toiletries, and personal care products in production and packaging facilities.

5. Industrial manufacturing: Used for handling various materials, components, and products in a wide range of industrial applications.

Overall, stainless steel conveyors are versatile and essential equipment in many industries where hygiene, durability, and reliability are crucial.

What makes stainless steel conveyors more demanding than other types of conveyors?`

ENTRA provides stainless steel conveyors for hygiene purposes.

Stainless steel components are easy to clean and very resistant to hostile chemicals. We provide modular components and parts, including split beams and matching drive units, idlers and guide rails, and support components. Series X components have stainless steel designs tailored to the needs of the food processing, pharmaceutical, and hygiene industries. The Series X system is also intended for seamless connection with aluminum systems.

ENTRA offers conveyor components such as beams, beam support brackets, end drive units, idler end units, guide rail profiles, guide rail brackets, wheel bends, plain bends, vertical bends, and support components.

Stainless steel conveyors are often considered better than steel conveyors for several reasons:

1. Corrosion resistance: Stainless steel has a higher resistance to corrosion compared to regular steel, making it ideal for applications where exposure to moisture or corrosive materials is a concern.

2. Hygiene: Stainless steel is non-porous and easy to clean,not like aluminum conveyors, making it suitable for industries where cleanliness and sanitation are critical, such as food processing and pharmaceuticals.

3. Strength and durability: Stainless steel is known for its strength and durability, allowing stainless steel conveyors to withstand heavy loads and harsh operating conditions better than regular steel conveyors.

4. Aesthetic appeal: Stainless steel has a sleek and modern appearance, making it a popular choice for industries where aesthetics are important, such as retail and hospitality.

Overall, stainless steel conveyors offer superior performance, longevity, and aesthetics compared to regular steel conveyors, making them a preferred choice for many industrial applications.

Stainless Steel conveyor types

Our Designs

Stainless Steel driven conveyor

Stainless Steel Bend Conveyor

Stainless Steel Curve conveyor

Stainless Steel slat conveyor

ENTRA Stainless steel conveyors including plastic chain and modular belt conveyors

Stainless steel conveyors are flexible, and hygienic chain conveyor systems use stainless steel beams. By reducing dirt pockets and emphasizing rounded surfaces for better drainage, the design adopts a proactive approach to improve cleaning.

The standardized system with top-notch parts makes assembly and installation simple, reduces startup time, and enables quick and simple line adjustments.

The stainless steel conveyor parts from ENTRA Conveyor systems are created to work in both primary and secondary packing applications that are demanding.

ENTRA stainless steel Conveyors handle crucial characteristics of modern packing procedures such ease of cleaning, smooth product handling, operator safety, sturdy design, extended life, and cheap cost for your production lines.

ENTRA stainless steel conveyor systems are comprised of two distinct DS2 and DL2 streamline assemblies and installation times, which allow rapid and relaxed line modifications. These stainless steel conveyors can function easily at high speeds without lubrication.

Our Conveyors in Egypt design comprehends trouble-free line configurations, site installation, and maintenance, making them cost-effective and simple to use.

Our stainless steel conveyors can be reconfigured or assembled in quite less time using simple hand-held tools.

Related Products

Inspired by our work?

Please fill out the form, so we can learn more about you and your needs.