🚀 Revolutionizing Material Handling in Egypt & the Middle East with Advanced Conveyor Systems

July 15, 2025🏭 Case Study: How ENTRA Boosted Efficiency for Alnast Chemicals Salt Factory in Egypt

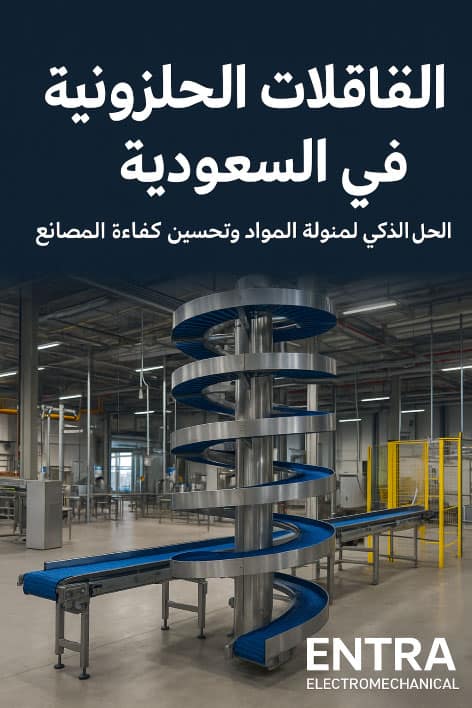

July 16, 2025Conveyor systems are the unsung heroes of industrial automation and logistics in the Middle East, where manufacturing, mining, and warehousing are experiencing rapid transformation. Whether it’s a cement plant in Egypt, a logistics hub in the UAE, or a pharmaceutical factory in Saudi Arabia, the right conveyor system can significantly increase throughput, safety, and efficiency.

In this article, we’ll explore the top 5 conveyor types powering factories across the region, how they work, and when to use them.

🔍 Why Conveyor Systems Are Vital in the Middle East

The Middle East conveyor system market is growing steadily, supported by automation trends and industrial mega projects like Egypt Vision 2030, NEOM in Saudi Arabia, and the UAE’s manufacturing diversification strategy.

According to ResearchAndMarkets.com, conveyor system usage in MENA is expected to grow at over 4.2% CAGR through 2028, driven by:

-

Increased demand for automated material handling

-

Government incentives for industrial modernization

-

Rising infrastructure and construction activity

-

Growth in food, cement, logistics, and packaging sectors

🔝 Top 5 Conveyor Types in Middle Eastern Factories

1️⃣ Belt Conveyors

🔧 What It Is:

A flexible loop of material (belt) that moves items from point A to B using pulleys and motors.

🏭 Best For:

-

Packaging plants

-

Warehouses

-

Food and beverage lines

-

Distribution centers

✅ Benefits:

-

Versatile and cost-effective

-

Handles a wide variety of materials

-

Easy to install and maintain

2️⃣ Screw Conveyors

🔧 What It Is:

A rotating helical screw inside a tube or trough that moves granular or semi-solid materials.

🏭 Best For:

-

Cement plants

-

Fertilizer factories

-

Waste treatment plants

-

Food processing (powdered ingredients)

✅ Benefits:

-

Excellent for bulk materials

-

Can be horizontal, inclined, or vertical

-

Sealed systems reduce dust and spillage

3️⃣ Roller Conveyors

Roller Conveyor @ Juhayna Milk Factory

🔧 What It Is:

A system of rollers on which items are manually pushed or moved by gravity or powered rollers.

🏭 Best For:

-

E-commerce and logistics hubs

-

Assembly lines

-

Parcel handling

✅ Benefits:

-

Great for flat-bottomed items

-

Scalable and modular

-

Can be gravity-based or motorized

4️⃣ Chain Conveyors

🔧 What It Is:

Conveyor system that uses chains to move heavy loads, especially in harsh environments.

🏭 Best For:

-

Steel manufacturing

-

Automotive plants

-

Foundries

✅ Benefits:

-

Heavy-duty and durable

-

Resistant to high temperatures and wear

-

Handles large pallets or bulky items

5️⃣ Bucket Elevators

🔧 What It Is:

A vertical conveyor that lifts bulk materials using attached buckets on a belt or chain.

🏭 Best For:

-

Grain elevators

-

Cement factories

-

Chemical production

✅ Benefits:

-

Vertical lift with minimal space

-

High throughput capacity

-

Fully enclosed for cleanliness and safety

⚙️ Choosing the Right Conveyor System for Your Factory

When choosing the optimal conveyor for your business, consider the following:

-

Type of material: granular, liquid, packaged, or bulky

-

Required throughput: low-volume or high-speed lines

-

Space limitations and layout

-

Cleanliness or contamination control needs

-

Level of automation desired

🔗 Internal Suggestion:Company Brochure

🏗️ ENTRA Electromechanical: Your Conveyor Partner in Egypt & the Middle East

At ENTRA, we provide custom-designed conveyor systems that fit the exact needs of your factory. With over 15 years of experience, we specialize in:

-

Screw, belt, chain, and roller conveyor manufacturing

-

On-site installation across Egypt and the Gulf

-

PLC integration and smart automation

-

Spare part support and preventive maintenance

📩 Contact us today for a free conveyor audit:

🌐 www.entra-eg.com | 📧 entra@entra-eg.com

🧠 Final Thoughts

Choosing the right conveyor system is essential to modern factory design. As factories in Egypt and the Middle East embrace Industry 4.0, conveyor automation will continue to be a core driver of efficiency, safety, and scalability.