How Smart Conveyor Systems Are Revolutionizing Material Handling

August 5, 2025

Step-by-Step Guide to Designing a Conveyor Layout for Your Plant

August 10, 2025The world of manufacturing is changing fast. Automation is no longer optional—it’s a must. Today, automated conveyor systems play a big role in modern factories. From sorting parcels to managing production flow, conveyors are smarter than ever. So, what’s new in 2025?

Let’s explore the latest automation trends making conveyor systems more efficient, flexible, and powerful.

AI Is Making Sorting Smarter

Artificial intelligence (AI) is transforming how items move across conveyors. Instead of humans operating diverters, AI can now do the job. Vision systems read barcodes, scan shapes, and decide where each item should go.

This process is faster and more accurate. In fact, modern AI can reduce misrouted items by over 80%. ENTRA Electromechanical offers systems powered by machine learning. These systems improve sorting with every cycle.

Why it matters: AI reduces errors, increases speed, and boosts productivity with less human effort.

Real-Time Data with IoT Sensors

IoT (Internet of Things) is another trend that’s changing conveyor systems. Sensors are now installed on rollers, motors, and belts. These sensors collect data in real time.

For example, they can detect:

-

Motor temperature

-

Belt tension

-

Product weight

-

Unusual vibrations

All this data is sent to a dashboard or control system. Maintenance teams get alerts before breakdowns happen. As a result, downtime is cut by up to 35%.

Bottom line: IoT makes conveyor systems smarter and more reliable.

Robotics Are Joining the Line

In 2025, automated conveyor systems often include robotics. Robots work together with conveyor belts to pick, place, lift, or rotate items.

Automated Guided Vehicles (AGVs) also carry materials between conveyor stations. This trend is very popular in large warehouses and e-commerce centers.

Robotic arms and conveyors now work as one system. Together, they handle tasks quickly and safely—no human needed on the line.

Impact: Robotics reduces labor costs and speeds up operations.

Predictive Analytics and Digital Twins

Data is powerful—but only if you use it right. That’s where predictive analytics come in. These tools study past performance to predict future issues.

Digital twins, which are virtual copies of conveyor systems, also help. Engineers use them to simulate production and fix problems before they happen.

This smart approach can:

-

Improve uptime by 30%

-

Reduce maintenance costs

-

Avoid unexpected failures

Why it’s key: Predictive tools let factories plan ahead and avoid delays.

Energy Efficiency Takes Center Stage

Energy prices are rising, especially in the Middle East. That’s why new conveyor systems focus on saving power.

Modern motors recover energy when they stop or slow down. This energy is reused to power other parts of the system. Also, many conveyors now sleep when idle, saving electricity.

These changes reduce power use by 10–15%. ENTRA’s systems already include energy-saving motors and smart power controls.

Result: Lower energy bills and a smaller carbon footprint.

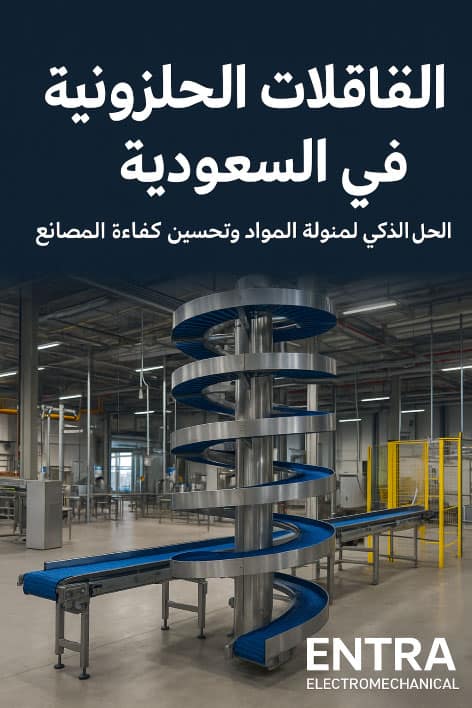

Modular Designs for Flexible Factories

Today’s factories need to adapt fast. That’s why modular conveyors are in high demand. These systems come in ready-made sections like:

-

Straight belts

-

Curves

-

Elevators

-

Turntables

You can add or remove sections as needed. If production changes, your conveyor layout can change too—no need for a full rebuild.

Advantage: Modular designs support growth and lean manufacturing.

Cloud Control and Mobile Access

Conveyor systems are now controlled from anywhere. Managers don’t need to be on-site. With cloud software, you can:

-

Monitor speed

-

Check performance

-

Pause or restart lines

-

Receive real-time alerts

You can even use your phone or tablet to manage systems remotely. This is perfect for 24/7 operations or multi-site factories.

Outcome: Faster response times and better control.

Industry Use Cases and Real Benefits

These automation trends are not just ideas—they’re already in action. ENTRA Electromechanical recently upgraded a cold-chain facility using:

-

AI diverters

-

IoT sensors

-

AGV integration

-

Predictive analytics

After the upgrade:

-

Throughput increased by 27%

-

Downtime dropped by 40%

This proves that automated conveyor systems with smart features give real ROI.

What to Look for When Upgrading

When choosing automation upgrades, ask your supplier about:

-

Sorting speed and AI accuracy

-

Sensor compatibility and alerts

-

Energy-saving features

-

Flexibility and layout options

-

Robot or AGV integration

ENTRA Electromechanical customizes every system to match your plant needs. Whether you manage a food plant, packaging center, or factory, automation can take your conveyor system to the next level.

Final Thoughts: Build for the Future

Automation is the future. In 2025, automated conveyor systems are smarter, cleaner, and more connected. By investing in AI, IoT, robotics, and modular designs, manufacturers improve productivity and reduce waste.

Don’t get left behind. Upgrade your conveyor systems now—and choose a provider that understands your industry.

Contact ENTRA Electromechanical today for a free consultation and site visit.