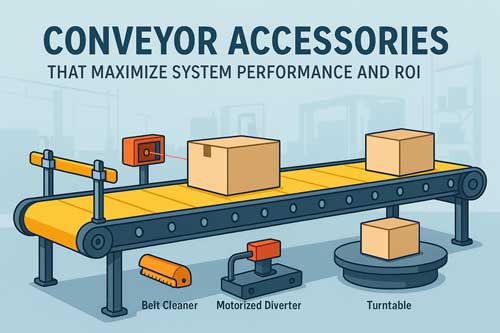

Conveyor Accessories That Maximize System Performance and ROI

August 3, 2025

How Smart Conveyor Systems Are Revolutionizing Material Handling

August 5, 2025🏗️ Introduction: The Hidden Power of Conveyor Accessories

In the world of material handling, conveyor systems take center stage—but the real efficiency often comes from the unsung heroes: conveyor accessories.

Whether you’re optimizing speed, safety, or functionality, choosing the right accessories can drastically improve your system’s performance. For industries relying on ENTRA Electromechanical conveyor solutions, accessories are not optional add-ons—they are integral to a well-oiled production line.

From rollers and sensors to side guides and diverters, these accessories fine-tune your operations and ensure your conveyor system works smarter, not harder.

🔧 1. What Are Conveyor Accessories?

Conveyor accessories refer to components added to a base conveyor to expand its functionality, improve safety, and enhance performance. These can be mechanical, electrical, or digital—each designed to address a specific operational need.

Common Types Include:

-

Conveyor rollers & idlers

-

Side guides & guardrails

-

Photoelectric sensors

-

Metal detectors

-

Skirts and scrapers

-

Diverters and sortation units

-

Emergency stop buttons

-

Drip pans and belt cleaners

✅ ENTRA Electromechanical offers tailor-made conveyor accessories designed for both belt and roller conveyors, fully compatible with Egyptian and GCC industry standards.

⚙️ 2. Why Conveyor Accessories Matter for Material Handling Efficiency

Without the right accessories, even the most advanced conveyor system may underperform. Here’s how conveyor accessories directly impact industrial outcomes:

🟩 A. Reduced Downtime

Belt cleaners and scrapers minimize debris accumulation, preventing jams and reducing maintenance intervals.

🟨 B. Enhanced Safety

Guardrails, emergency stops, and anti-slip features reduce workplace accidents—a critical factor in food, pharma, and logistics industries.

🟦 C. Increased Throughput

Accessories like diverters and motorized switches help control product flow and sorting, improving system adaptability.

🟧 D. Cost Efficiency

Modular accessory upgrades are often cheaper than overhauling full conveyor systems, offering a strong ROI.

🏭 3. Top Accessories Used in Egyptian Manufacturing Plants

ENTRA Electromechanical, headquartered in Giza, Egypt, provides the following accessories for various industries:

| Accessory | Use Case | Industry |

|---|---|---|

| Side guides | Prevent product fall-off | FMCG, Retail, Warehousing |

| Metal detectors | Quality control | Food & Pharma |

| Rollers & Idlers | Smooth motion | Heavy Manufacturing |

| Diverters | Sorting | Packaging |

| Sensor units | Speed and location control | E-commerce logistics |

💡 4. How to Select the Right Conveyor Accessories

When choosing conveyor accessories, consider the following:

-

Conveyor Type: Belt vs. Roller vs. Slat

-

Material Type: Size, shape, weight, fragility

-

Speed & Volume: High-speed conveyors may need advanced sensors or diverters

-

Environment: Dust, moisture, temperature

ENTRA provides on-site consultancy to assess your needs and recommend optimal accessories accordingly.

🤖 5. Automation-Ready Conveyor Accessories

Industry 4.0 is reshaping logistics. Smart conveyor accessories enable seamless integration with PLC systems, ERP, and IoT sensors.

Must-Have Automation Components:

-

Photoelectric Sensors: Detect presence and direction of items

-

Barcode Scanners: For WMS integration

-

Pneumatic Pushers: For automated sorting

-

Motorized Rollers: Controlled acceleration & deceleration

-

Servo Diverts: High-speed lane switching

🧠 ENTRA integrates Siemens and Schneider Electric accessories for enhanced automation in Egypt’s top logistics hubs.

🔄 6. Maintenance & Reliability: Accessories that Extend Lifespan

Proper accessory implementation reduces wear and tear on your conveyor system.

Maintenance-Friendly Components:

-

Self-lubricating idlers

-

Quick-release belt cleaners

-

Modular guide rails

-

LED status indicators

By scheduling preventive maintenance based on accessory sensor data, facilities can cut downtime by over 30%.

📈 7. Case Study: Conveyor Accessory Upgrade at a Giza Cold Storage Facility

Client: Large-scale food distributor

Problem: Belt contamination due to excess product debris

Solution:

-

ENTRA-installed dual-blade belt cleaners

-

Side skirts to minimize product spill

-

Metal detector unit for outbound QA

Result:

-

43% reduction in maintenance frequency

-

25% fewer rejected pallets

-

ROI in 4.5 months

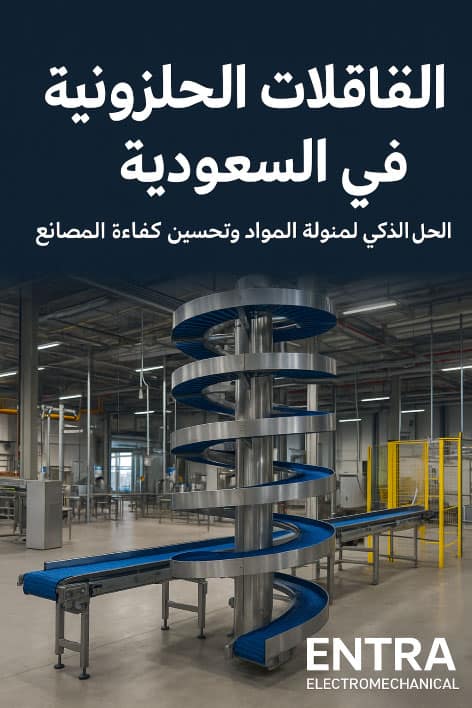

🏆 8. Why ENTRA Electromechanical ?

-

🇪🇬 Egyptian manufacturing with GCC-standard quality

-

🛠️ Customized accessories for legacy and modern systems

-

🖥️ Full integration with SCADA, WMS & ERP platforms

-

🧩 Modular upgrades for every conveyor type

-

💬 Post-sales service and annual accessory servicing

Visit entra-eg.com or request a free accessory assessment today.

🔚 Conclusion: Small Add-ons, Big Impact

In a competitive manufacturing landscape, every second counts—and every component matters. Conveyor accessories may seem minor, but they are critical for achieving precision, speed, and safety.

By partnering with ENTRA Electromechanical, Egyptian and Middle Eastern manufacturers gain access to customized, high-performance accessory solutions tailored to their exact needs.