Boosting Warehouse Efficiency with Pallet Handling Conveyors: A Strategic Guide for Plant Operations

July 30, 2025

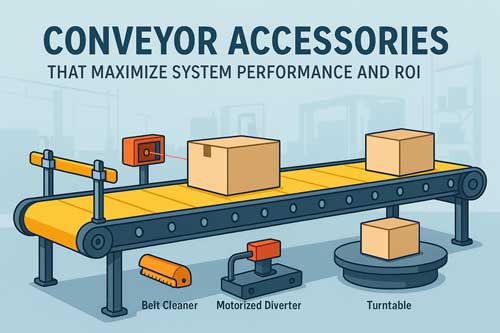

Unlocking Efficiency: How Conveyor Accessories Elevate Material Handling Performance

August 4, 2025When we talk about conveyor systems, most of the attention goes to the main belts, rollers, and motors. But what often makes the real difference in performance, safety, and ROI are the conveyor accessories.

In this article, we’ll dive deep into the top conveyor add-ons used in industrial material handling systems, particularly those in high-demand environments like factories, packaging centers, and distribution warehouses.

Whether you’re managing an upgrade or designing from scratch, understanding how to leverage these accessories can result in faster throughput, lower downtime, and a safer work environment.

🔧 1. What Are Conveyor Accessories?

Conveyor accessories are auxiliary components installed alongside the primary conveyor system. They’re not always mandatory but play a critical role in:

-

Enhancing operational control

-

Improving safety and ergonomics

-

Automating specialized tasks

-

Extending the lifespan of conveyor equipment

✅ ENTRA Electromechanical integrates custom accessories into their conveyor lines based on application type, product size, and plant flow.

🧰 2. Top Conveyor Accessories You Should Know

Here’s a breakdown of the most effective accessories in use today:

a) Guides and Rails

-

Prevent product from falling or shifting on belts.

-

Adjustable models allow handling of multiple product sizes.

b) Photoelectric and Proximity Sensors

-

Detect product position and presence.

-

Crucial for accumulation, sorting, and safety mechanisms.

c) Conveyor Belt Cleaners

-

Remove debris and buildup from belts.

-

Extend belt life and improve hygiene (essential in food-grade systems).

d) Motorized Diverters and Pushers

-

Redirect items from one lane to another automatically.

-

Ideal for e-commerce and order-picking zones.

e) Stops, Gates, and Lift Gates

-

Control flow and access in specific areas.

-

Useful during maintenance or loading/unloading.

f) Weighing Systems and Scales

-

Automatically weigh materials during movement.

-

Integrated with WMS/ERP for inventory accuracy.

g) Side Transfers and Turntables

-

Rotate or transfer products at 90° or 180° angles.

-

Useful for product orientation or direction changes.

h) Conveyor Covers and Enclosures

-

Protect sensitive products from dust or contaminants.

-

Common in pharmaceuticals, food, and electronics industries.

💼 3. Where Accessories Make the Biggest Impact

These accessories are particularly valuable in:

| Sector | Impact |

|---|---|

| FMCG | High-speed sensors, diverters for sorting SKUs |

| Pharmaceuticals | Belt cleaners, side rails, and covers for hygiene |

| Automotive | Turntables and side transfers for part orientation |

| Warehousing & 3PL | Accumulation sensors, lift gates, and pushers for distribution lines |

| Cold Chain Logistics | Enclosures, anti-slip belts, and belt heaters |

🏭 ENTRA recently upgraded a major Giza-based warehouse with diverters and smart sensors, reducing misrouted parcels by 87%.

💡 4. How Accessories Improve Efficiency and Safety

| Benefit | Description |

|---|---|

| Increased Throughput | Smart diverters and sensors reduce human decision points. |

| Error Reduction | Sensors and stops reduce product mix-ups and misrouting. |

| Operator Safety | Lift gates and barriers keep personnel out of danger zones. |

| Equipment Protection | Belt cleaners and covers prevent wear and contamination. |

| Maintenance Savings | Reduced mechanical wear and downtime due to overload prevention accessories. |

📐 5. Design Considerations When Adding Accessories

Before investing, consider:

-

Conveyor speed and load

-

Available space

-

Automation level

-

Product type and size

-

Integration with WMS or PLCs

ENTRA offers custom-fit solutions to ensure accessories enhance rather than disrupt existing operations.

🔗 6. Smart Integration with Automation Systems

Modern accessories are often IoT-ready or built for smart factory environments:

-

Barcode scanners integrated with WMS

-

PLC-connected sensors triggering diverters or alarms

-

RFID-enabled stops for real-time inventory flow

🔧 ENTRA uses Schneider and Siemens automation modules to ensure seamless accessory integration in Industry 4.0 environments.

📊 7. Cost vs ROI Breakdown

| Accessory Type | Avg. Cost (EGP) | Typical ROI Period |

|---|---|---|

| Sensors and Scanners | 3,000 – 12,000 | 3–6 months |

| Diverters and Pushers | 15,000 – 35,000 | 6–12 months |

| Belt Cleaners | 2,500 – 7,000 | 2–4 months |

| Turntables & Transfers | 20,000 – 50,000 | 8–14 months |

💰 Smart investment in accessories can pay back in under a year with reduced errors and higher output.

🌟 8. Why ENTRA Electromechanical for Conveyor Accessories?

-

15+ years of industrial conveyor experience

-

Local sourcing of parts and custom fabrication in Egypt

-

Integration with existing lines or new setups

-

Expert engineering team to match every application

-

Post-installation training and servicing plans

Contact entra-eg.com to get a tailored accessory recommendation for your plant setup.

📌 Conclusion

Whether you’re upgrading a legacy line or designing a new smart facility, conveyor accessories should not be an afterthought.

From simple guides to advanced diverters and IoT sensors, each accessory adds value, precision, and productivity.

With ENTRA’s modular design approach and local Egyptian manufacturing base, getting the right accessory has never been easier or more cost-effective.