How Pallet Handling Conveyors Improve Efficiency in Manufacturing Plants

July 27, 2025

How Pallet Handling Conveyors Enhance Logistics Efficiency in Manufacturing Plants

July 29, 2025🚀 Introduction

In today’s competitive industrial landscape, maximizing efficiency, safety, and system reliability is not a luxury—it’s a necessity. For those managing or designing conveyor systems, one critical yet often overlooked factor is the selection and implementation of conveyor accessories.

From belt cleaners to guiding systems and sensors, these accessories can make or break the performance of your material handling equipment. In this guide, we dive into the essential conveyor accessories that every manufacturing plant should consider, especially if you’re aiming to boost uptime, reduce maintenance, and optimize flow.

🧠 Why Conveyor Accessories Matter

Before diving into the list, let’s clarify why these components are not optional:

-

🌟 Enhance safety: Prevents slippage, misalignment, and hazardous buildup.

-

⏱️ Increase efficiency: Minimizes downtime with automated features and preventive components.

-

💰 Lower costs: Reduces wear and energy waste, extending system life.

-

🛠️ Improve maintenance: Diagnostic tools and guards make troubleshooting easier and safer.

Whether you’re using belt conveyors, pallet handling conveyors, or automated conveyor systems, the right accessories complement your system for optimal results.

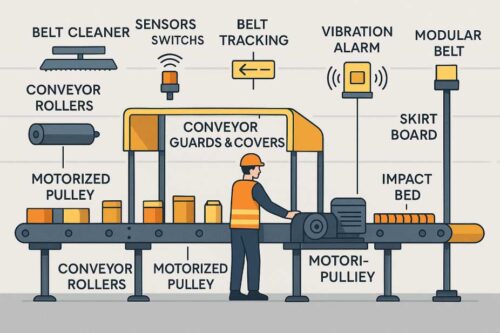

🔧 Top 10 Essential Conveyor Accessories You Should Know

1. Belt Cleaners (Scrapers)

-

Function: Removes excess material from the conveyor belt.

-

Why it matters: Prevents material buildup, reducing maintenance and improving cleanliness.

-

Use case: Cement plants, bulk material handling in mining and food industries.

2. Conveyor Guards & Covers

-

Function: Shields moving parts and keeps personnel safe.

-

Why it matters: OSHA compliance and accident prevention.

-

Use case: Any plant following industrial safety protocols.

3. Impact Beds and Bars

-

Function: Absorb shock at loading zones to protect belts and idlers.

-

Why it matters: Reduces belt damage and spillage.

-

Use case: Bulk loading zones, mining, construction aggregates.

4. Belt Tracking Devices

-

Function: Ensures the belt stays centered and aligned.

-

Why it matters: Prevents wear and system breakdowns.

-

Use case: Long-distance belt conveyors, curved layouts.

5. Conveyor Sensors and Switches

-

Function: Detect movement, alignment, load levels, and more.

-

Why it matters: Automates system diagnostics and safety shutoffs.

-

Use case: Smart manufacturing, automated factories.

6. Skirt Boards and Sealing Systems

-

Function: Prevents spillage at loading/unloading zones.

-

Why it matters: Reduces dust, waste, and product loss.

-

Use case: Cement, fertilizer, or grain handling lines.

7. Conveyor Rollers (Carrying & Return)

-

Function: Support the belt and ensure smooth operation.

-

Why it matters: Lower friction, less energy, extended belt life.

-

Use case: Universal, especially in high-speed conveyors.

8. Motorized Drive Pulleys

-

Function: Drive the belt efficiently with enclosed motors.

-

Why it matters: Compact, energy-efficient, less maintenance.

-

Use case: Cleanroom or space-constrained environments.

9. Vibration and Misalignment Alarms

-

Function: Alert for abnormal operation.

-

Why it matters: Prevents major failures through early detection.

-

Use case: Facilities with remote or long conveyor runs.

10. Modular Belt Attachments

-

Function: Add features like side guards, bucket cleats, etc.

-

Why it matters: Customizable for specific product shapes or flow types.

-

Use case: Food processing, parcel handling, automotive.

🏭 Real-Life Use Case: ENTRA Electromechanical’s Accessory Integration

At ENTRA Electromechanical, the integration of accessories into their motorized conveyor systems ensures that their Egyptian and Middle Eastern clients experience minimum downtime and maximum efficiency.

A 2024 project in Al Obour involved customizing a belt conveyor system with:

-

Dual-speed motors

-

Skirt boards

-

Auto-clean scrapers

-

Sensor-activated tracking

The result? A 31% reduction in maintenance time and 20% fewer operational stoppages.

📦 Choosing the Right Accessories: A Procurement Checklist

| Requirement | Suggested Accessory |

|---|---|

| High-speed flow | Balanced rollers, alignment sensors |

| Dust-free environment | Sealing systems, covers |

| Heavy impact zones | Impact beds, reinforced frames |

| Food grade materials | Stainless steel accessories, modular belts |

| Remote operation | Sensors + smart alarms |

🔄 Integration Tips for Engineers

-

⚙️ Design with modularity: Choose plug-and-play accessories for future upgrades.

-

🧪 Test in stages: Add accessories incrementally to evaluate impact.

-

💡 Use smart tech: Integrate with PLCs and IoT for real-time monitoring.

-

📐 Account for load zones: Choose the right impact and sealing accessories at key transfer points.