Modular Conveyors

The Rise of Modular Conveyor Systems in Egyptian Manufacturing

Egypt’s industrial sector has been experiencing rapid growth, with manufacturing facilities adopting innovative technologies to stay competitive in the global market. Among these technologies, modular conveyor systems have emerged as a game-changer for Egyptian businesses looking to optimize their production processes.

What Makes Modular Conveyor Systems Ideal?

Modular conveyor systems offer unparalleled flexibility and scalability—qualities particularly valuable in Egypt’s diverse and evolving industrial landscape. Unlike traditional fixed conveyor installations, modular systems can be easily reconfigured, expanded, or modified as production needs change.

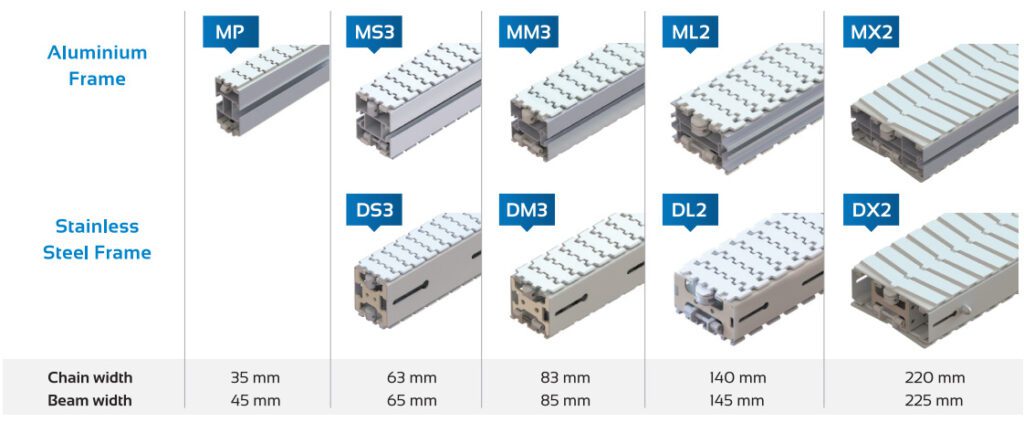

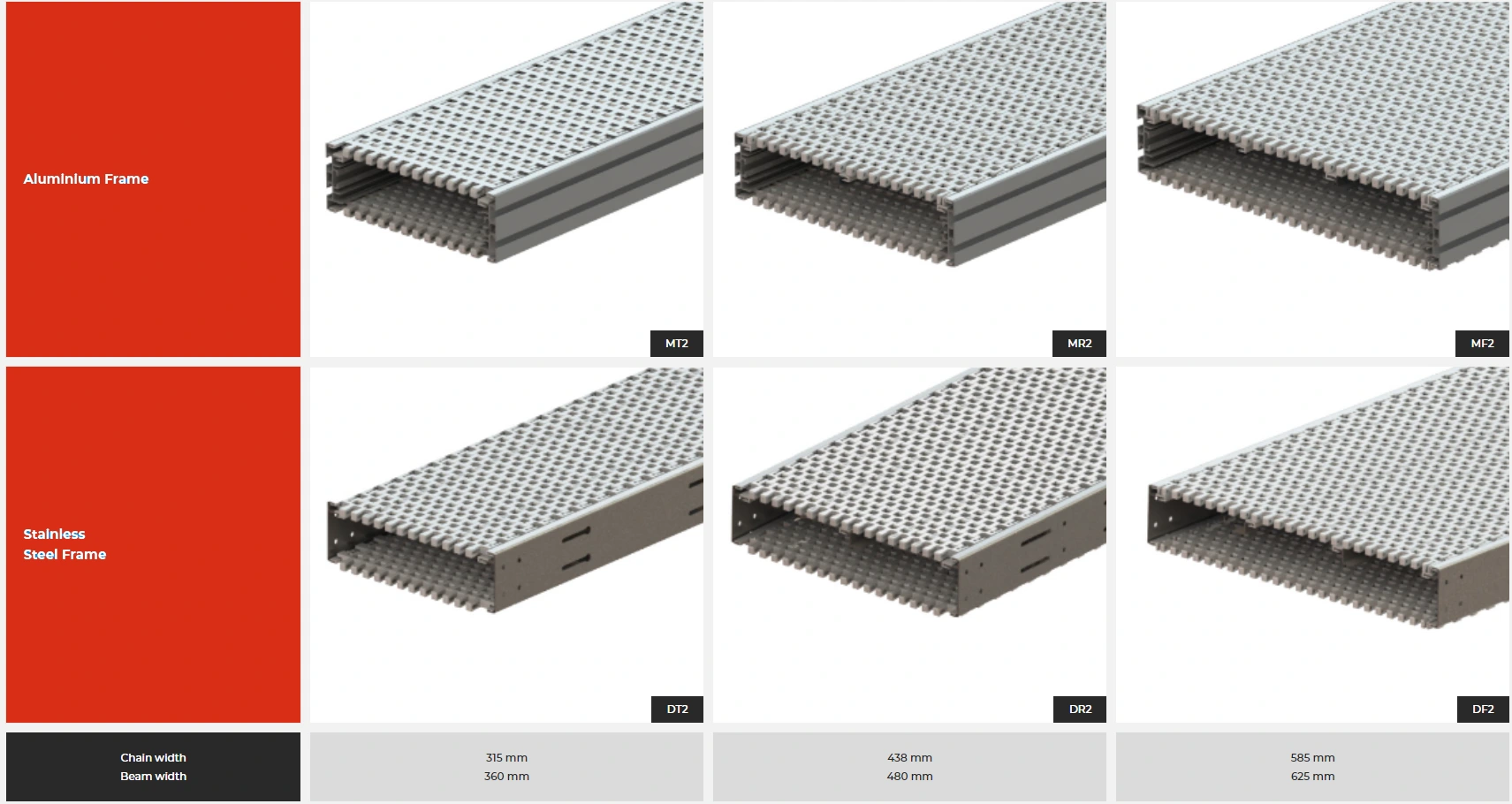

Types of Modular Conveyors Available in the Egyptian Market

Key Benefits of Modular Conveyors for Egyptian Businesses

Implementing modular conveyor systems offers key advantages for Egyptian manufacturers and distributors:

- Operational Flexibility: Easily reconfigured to adapt to changing product types, volumes, or seasons, helping businesses stay competitive and utilize existing infrastructure efficiently.

- Cost-Effective Scaling: Allows companies to start small and expand gradually, reducing initial costs and enabling targeted maintenance to lower long-term expenses.

- Space Optimization: Designed to maximize limited space, using vertical and compact configurations, freeing up floor area for other production needs.

- Reduced Downtime: Modular design enables quick maintenance and parts replacement, minimizing production stops—especially important given import delays and part availability issues in Egypt.

Overall, these systems support agility, cost savings, and efficient use of space in Egypt’s evolving industrial landscape.

Modular Plastic Chain

Modular Plastic Belt

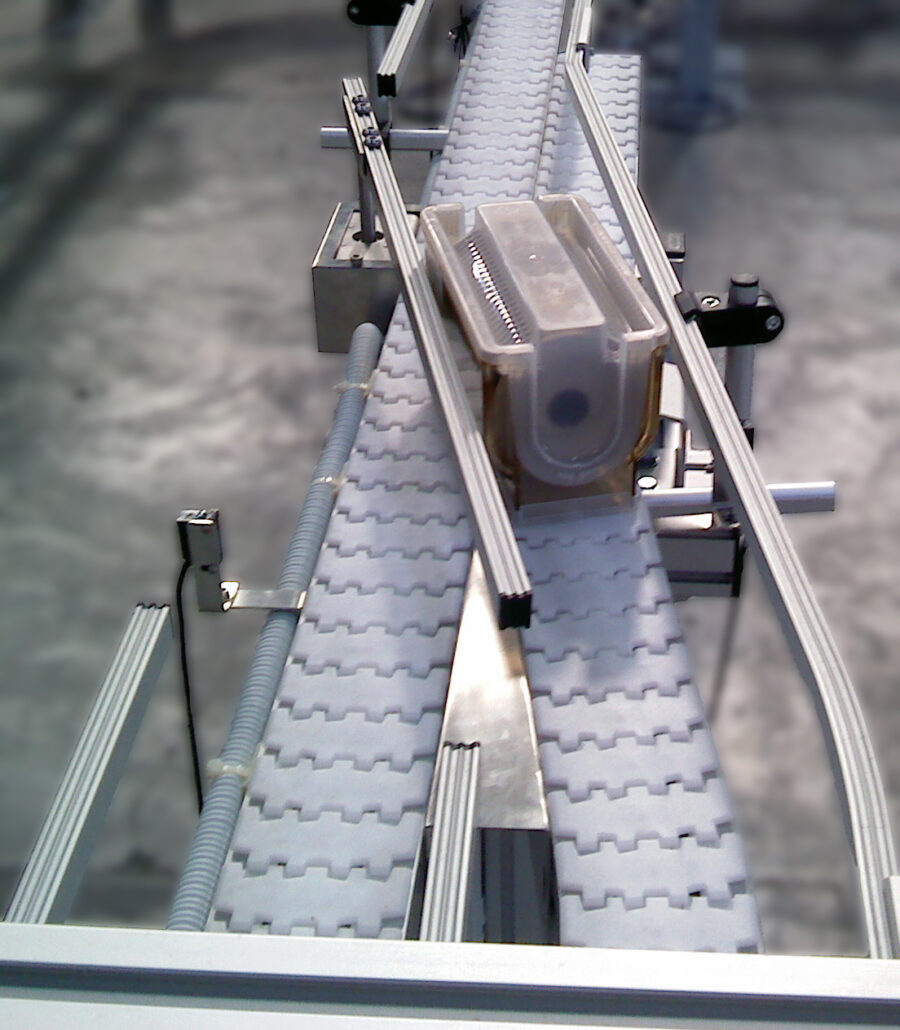

MODU’s new modular plastic belt conveyor system is a simplified solution for conveying large products.

All components of the plastic belt conveyor are standardized for easy engineering, maintenance, and operation. Simplicity in its design makes the System’s new plastic belt conveyor reliable, flexible, safe, and adaptive to any requirements.

The white POM belt surface is flat and smooth, which minimizes the risk of scratches on products, allowing safe handling of sensitive products. Plastic belt conveyor systems are designed to integrate with new and existing production equipment.

Machinery that has been laid out to fulfill Factory and operator requirements can easily be linked using suitable components and conveyors from our modular range.

PRODUCTS INTRODUCTION

Other Modular Conveyor Technologies

beyond belt-based systems, the modular concept has been extended to other conveyor types to cater to diverse operational needs:

- Modular Roller Conveyors: These systems utilize a series of individual rollers arranged in a modular design. They are suitable for applications requiring the transportation of rigid or semi-rigid items. Modular roller conveyors are known for their durability and ease of assembly in high throughput environments like packaging lines and distribution centers.

- Gripper Conveyors: Designed for product handling in assembly lines where items need to be securely grasped and moved, gripper conveyors utilize modular sections to facilitate seamless transitions between different parts of the production process.

- Modular Plastic Chain Conveyors: Although less common, some manufacturers offer modular versions of plastic chain conveyors, providing the benefits of low maintenance and flexible layout options, especially in industries where washdown procedures are frequent.

In each case, the principles of modularity—standardization, ease of maintenance, and customizable design—remain central, providing Egyptian manufacturers with the versatility to adapt to rapidly evolving operational demands.

5. Applications Across Industries

The versatility of modular conveyor systems has led to their widespread adoption in a range of industrial sectors across Egypt. Their resilient design, adaptability, and compliance with high safety standards make them suitable for both heavy-duty manufacturing and high-hygiene environments.

Food Processing

Modular plastic belt conveyors are particularly favored in the food processing industry for several reasons:

- Hygiene and Sanitation: The ability to disassemble and clean the belts thoroughly is crucial in food processing applications to meet stringent health standards and avoid contamination

- Efficient Material Handling: They facilitate the swift movement of packaged goods, raw ingredients, and processed items, thereby ensuring smooth production flows in factories and packaging facilities

Pharmaceutical and Medical Industries

In pharmaceutical operations, the safe and efficient transfer of materials is critical:

- Compliance with cGMP Regulations: Modular conveyors designed for pharmaceutical use are built to strict cleanliness and quality standards. Compliance with current Good Manufacturing Practices (cGMP) and ISO 14644 is essential for these systems

- Specialized Designs: Systems may include specially designed cleats and modules that ensure products are not damaged during transport, guaranteeing the integrity of sensitive materials.

Manufacturing and Assembly Lines

Modern manufacturing facilities, including automotive and electronics assembly plants, rely heavily on modular conveyor systems:

- Increased Productivity: Conveyor systems ensure that parts and components are delivered precisely when needed, minimizing storage issues and optimizing production rates.

- Custom Configuration: Modular systems allow for significant customization. Manufacturers can design conveyors with specific layouts, speeds, and transfer points to suit the exact needs of their production lines

Agriculture and Packaging

In agricultural processing and contract packaging, modular conveyors are invaluable:

- Adaptability: Systems that integrate modular plastic chain conveyors or modular roller conveyors can handle diverse products—from agricultural produce to packaged consumer goods—with minimal adjustments

- Cost Efficiency: The ease of maintenance and modular design reduces the long-term costs associated with equipment downtime and operational inefficiencies

Table: Comparison of Modular Conveyor Systems by Application

| Conveyor Type | Key Features | Primary Applications | Advantages | Limitations |

|---|---|---|---|---|

| Modular Belt Conveyors | Segmented belt design, positive drive | Warehousing, packaging, assembly | Ease of maintenance, customization, durability | Not ideal for loose granular materials |

| Modular Plastic Belt Conveyors | Durable plastics (PE, PP, Acetal), hygienic design, easy cleaning | Food processing, pharmaceuticals, hygiene-critical industries | Fast repair, hygienic, low energy consumption | Higher initial cost, speed limitations |

| Inclined Modular Belt Conveyors | Variable angles (30°, 45°, 60°), robust aluminum frames | Food, molded parts, packaging lines | Adaptable to elevation changes, enhanced safety | Complex installation, higher upfront investment |

| Modular Roller & Gripper Conveyors | Modular rollers or gripper mechanisms, flexible layout | Manufacturing, assembly lines, logistics | Durable, adaptable to varying product sizes | Specific customization required, potential higher complexity |

Table Explanation: This table provides an overview of different modular conveyor systems by highlighting their key features, primary applications, advantages, and limitations. It is designed to assist manufacturers and engineers in making informed decisions about which system best fits their operational needs

Technical Aspects and Safety Compliance

Ensuring safety and regulatory compliance is critical in every aspect of conveyor system design and integration. Egyptian modular conveyor systems must adhere to both international guidelines and local industrial safety regulations.

Regulatory and Compliance Standards

Compliance with Safety Regulations:

Non-compliance with conveyor belt and modular conveyor safety regulations can lead to severe workplace accidents, financial penalties, and legal repercussions. Regulatory authorities impose fines and strict oversight measures that enforce adherence to safety standards to safeguard employee health and maintain operational efficiency. In Egypt, manufacturers like ENTRA Systems integrate guidelines from:

- ISO Certification: ENTRA follows ISO 9001:2015 among other relevant certifications to ensure quality management and operational consistency.

- Egyptian Organization for Standardization: Local standards further specify the criteria for materials, installation, and safe operation of conveyor systems

- National Safety Regulations: These include mandatory safety features, regular maintenance protocols, and compliance with operational best practices to ensure a safe working environment.

Compliance in Practice:

Engineering teams must rigorously test and inspect conveyor systems at every stage of assembly. Regular audits and documentation practices—supported by state-of-the-art technologies like real-time monitoring systems and IoT sensors—help in early detection of potential failures. Such systems not only bolster safety but also contribute to the longevity and efficiency of the equipment.

In conclusion, Egyptian modular conveyor systems represent a cutting-edge solution tailored to meet the diverse demands of modern manufacturing and processing industries.

From modular belt conveyors and modular plastic belt conveyors to inclined systems, these technologies offer significant benefits in terms of efficiency, safety, and customization.

Adherence to stringent safety and compliance standards—notably ISO certification, Egyptian industrial guidelines, and national safety regulations—ensures that these systems continuously deliver robust performance while protecting both workers and company assets.

Frequently Asked Questions about Modular Conveyors

What are modular conveyor systems, and why are they used in Egypt?

Modular conveyor systems are material handling solutions built from standardized, interchangeable components. They are used in Egypt to improve operational efficiency, reliability, and flexibility in manufacturing and processing industries. These systems automate material transport, reduce downtime, and enhance safety

What types of modular conveyor systems are commonly used in Egypt?

Common types include:

- Modular Belt Conveyors: Versatile systems using interlocking plastic or steel belts, easily modified for different widths and configurations .

- Modular Plastic Belt Conveyors: Ideal for industries requiring high hygiene standards, such as food processing and pharmaceuticals .

- Inclined Modular Belt Conveyors: Used to transport materials between different elevations, often incorporating features like cleats and sidewalls to prevent slippage .

- Modular Roller Conveyors: Suitable for transporting rigid items in high-throughput environments

In which industries in Egypt are modular conveyor systems most commonly used?

They are widely used in food processing, pharmaceuticals, manufacturing, assembly lines, agriculture, and packaging

What are the benefits of using modular belt conveyors?

Benefits include ease of maintenance, durability, and customization. Their segmented design allows for quick replacement of worn or damaged modules, reducing downtime. They can be easily adapted with altered belt widths and specialized cleats

Why are modular plastic belt conveyors popular in the food processing industry in Egypt?

Because they are easy to clean and sanitize, which is crucial for meeting hygiene standards and preventing contamination in food processing. Their interlocking design allows for quick disassembly and thorough cleaning.

What regulations and safety standards apply to modular conveyor systems in Egypt?

Egyptian modular conveyor systems must adhere to both international guidelines and local industrial safety regulations.

This includes ISO certifications and standards from the Egyptian Organization for Standardization. Companies like ENTRA Systems integrate these guidelines to ensure quality management and operational consistency