ENTRA Belt Conveyors: A Comprehensive Guide

November 23, 2024

ENTRA: Revolutionizing Digital Solutions in Egypt Through Strategic Partnership with MODU System

December 2, 2024Screw Conveyors in Egypt: The Ultimate Guide to Industrial Material Handling Solutions (2024 Updated)

Modern screw conveyor installation in an Egyptian industrial facility

Key Takeaways ⭐

- Comprehensive overview of the Egyptian screw conveyor market

- Industry-specific applications and standards

- Maintenance best practices and local support

- Cost considerations and ROI analysis

- Technical specifications and compliance requirements

Understanding the Egyptian Screw Conveyor Market: 2024 Industry Analysis

The Egyptian industrial sector’s material handling requirements have grown exponentially, with the screw conveyor market reaching EGP 1.2 billion in 2024. From Alexandria’s maritime industrial complexes to Cairo’s manufacturing zones, these systems form the backbone of Egypt’s industrial material transport infrastructure.

Market Growth Statistics:

- 15% annual growth in industrial automation sector

- 40% increase in local manufacturing capability

- 25% rise in demand for food-grade conveyors

- 30% expansion in cement industry applications

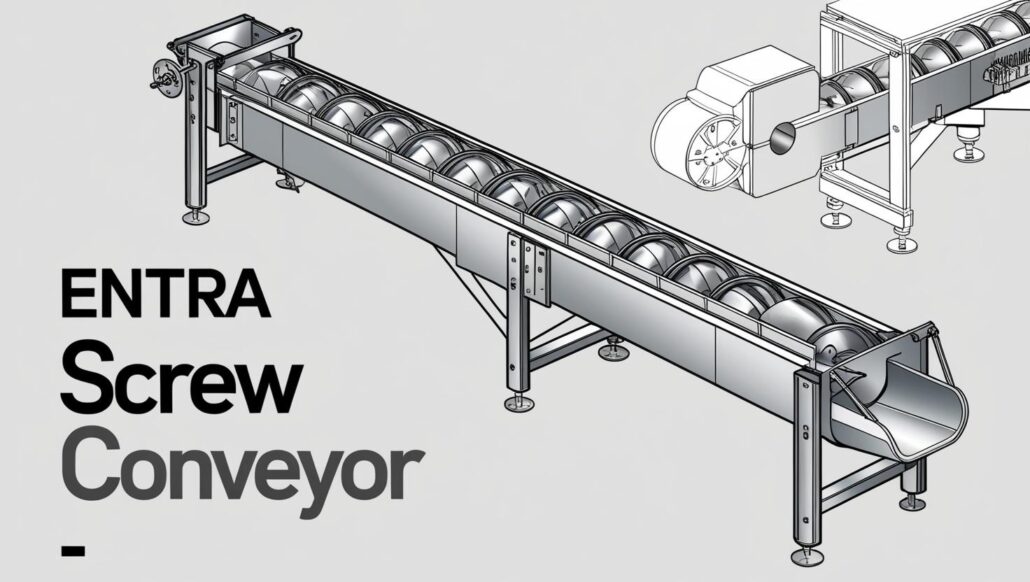

Industrial Applications and Manufacturing Excellence

Food Grade Screw Conveyors in Egyptian Processing Plants 🏭

Latest Innovations in Food Safety:

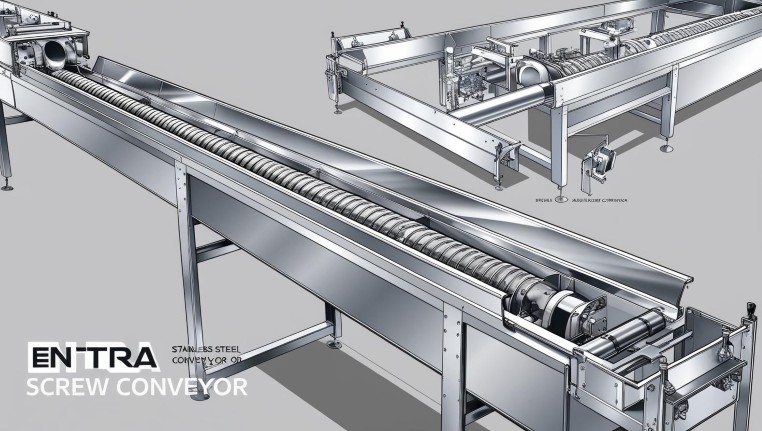

- HACCP-compliant stainless steel design

- Advanced clean-in-place (CIP) systems

- Real-time monitoring capabilities

- IoT-enabled performance tracking

- Automated sanitization protocols

Cement Industry Applications and Heavy-Duty Solutions 🏗️

Enhanced Performance Features:

- Reinforced flight design for abrasive materials

- High-torque drive systems

- Advanced dust containment

- Temperature-resistant components

- Automated load monitoring

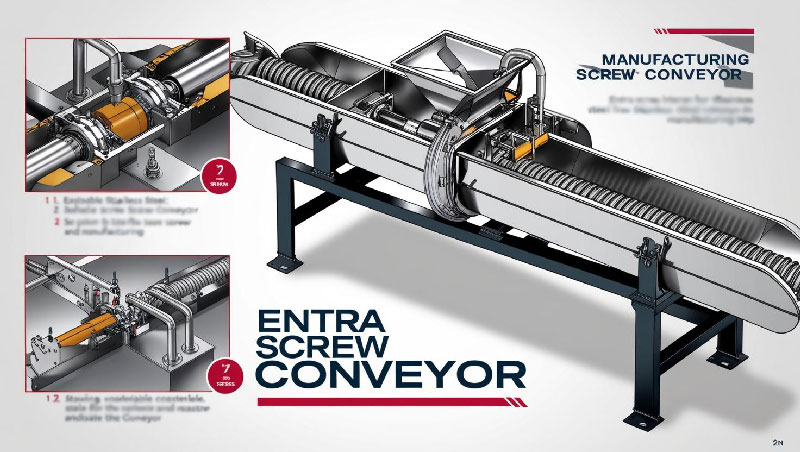

Technical Specifications and Engineering Innovation

Design and Capacity Optimization for Egyptian Standards

Advanced Engineering Considerations:

CopyCapacity = π/4 × D² × S × N × ψ × ρ × 60

Where:

D = Screw diameter (m)

S = Screw pitch (m)

N = Rotational speed (rpm)

ψ = Loading efficiency

ρ = Material bulk density (kg/m³)

New Section: Digital Integration and Industry 4.0

Smart Monitoring Systems

- Real-time performance analytics

- Predictive maintenance algorithms

- Remote operation capabilities

- Energy consumption optimization

- Integration with factory management systems

Sustainable Operations

- Energy-efficient motor systems

- Reduced carbon footprint designs

- Water conservation features

- Recyclable component options

- Green manufacturing practices

Enhanced Maintenance and Support Services

Professional Maintenance Solutions Across Egypt 🔧

Comprehensive Service Packages:

- 24/7 emergency response teams

- Scheduled preventive maintenance

- Performance optimization services

- Component life-cycle tracking

- Digital maintenance logging

FAQ Section:

Q: What is the average ROI timeline for screw conveyor systems in Egypt? A: Based on current market data, most Egyptian facilities achieve ROI within 18-24 months, depending on usage intensity and maintenance practices.

Q: How do Egyptian environmental conditions affect screw conveyor performance? A: Desert conditions require specialized dust sealing and temperature-resistant components. Our systems incorporate advanced protection against sand and heat exposure.

Q: What are the latest technological advancements in Egyptian screw conveyor systems? A: Recent innovations include IoT integration, AI-powered monitoring, energy-efficient drives, and advanced material coating technologies.

Q: How do local regulations affect screw conveyor installations? A: Egyptian industrial regulations require compliance with both local safety standards and international CEMA guidelines. Regular inspections and certifications are mandatory.