Behind the Scenes: ENTRA’s Conveyor Manufacturing Process

July 21, 2025

How Material Handling Equipment Can Improve Plant Efficiency

July 23, 2025Table of Contents

-

Introduction

-

Why Conveyor Systems Are Vital in Modern Manufacturing

-

Core Categories of Conveyor Systems

-

Belt Conveyors

-

Roller Conveyors

-

Chain Conveyors

-

Pallet Handling Conveyors

-

Overhead Conveyors

-

-

Automated Conveyor Systems: A Game Changer

-

Key Benefits of Advanced Conveyor Systems

-

Factors to Consider Before Choosing a Conveyor System

-

Industry-Specific Conveyor Use Cases

-

Conveyor Accessories That Boost Performance

-

Conveyor System Case Study: Lean Manufacturing Integration

-

Future Trends in Conveyor System Design

-

Conclusion

-

Frequently Asked Questions (FAQs)

1. Introduction

Manufacturing is evolving faster than ever in 2025. Companies are under constant pressure to improve productivity, reduce costs, and minimize downtime. One of the most powerful ways to achieve this is by integrating advanced conveyor systems into plant workflows.

In this guide, we’ll explore the top conveyor systems available in 2025, explain their industrial use cases, and show how they support streamlined operations across various sectors.

2. Why Conveyor Systems Are Vital in Modern Manufacturing

Conveyor systems are no longer just about moving items from point A to B—they’re the backbone of process automation in modern manufacturing.

Key Roles They Play:

-

Transporting raw materials and finished products

-

Automating repetitive tasks

-

Supporting just-in-time (JIT) production

-

Enhancing safety by minimizing manual handling

-

Providing real-time tracking via sensors and controls

Whether you’re in automotive, food processing, logistics, or heavy industry, optimized conveyor systems are now essential.

3. Core Categories of Conveyor Systems

Understanding the primary types of industrial conveyors is the first step toward selecting the right system for your plant:

🔹 Belt Conveyors

Keyword Target: Belt conveyors

Belt conveyors are the most common type due to their versatility. They use a continuous belt loop powered by pulleys to move products smoothly.

Best For:

-

Light to medium-weight products

-

Food production

-

E-commerce & distribution centers

Materials: PVC, PU, rubber, modular plastic

🔹 Roller Conveyors

Ideal for moving items with a flat, rigid bottom (like boxes or totes).

Types:

-

Gravity roller

-

Powered roller

-

Accumulating roller

Applications: Warehousing, sorting, palletizing

🔹 Chain Conveyors

Chain-driven systems are built for heavy-duty operations, moving parts or pallets that require high torque.

Used In: Automotive, steel, and bulk material handling industries

🔹 Pallet Handling Conveyors

Keyword Target: Pallet handling conveyors

Specialized systems designed for moving full pallets of goods. Often integrated with automated storage and retrieval systems (ASRS).

Features:

-

High load capacity

-

Chain or roller-based designs

-

Compatible with forklifts and robots

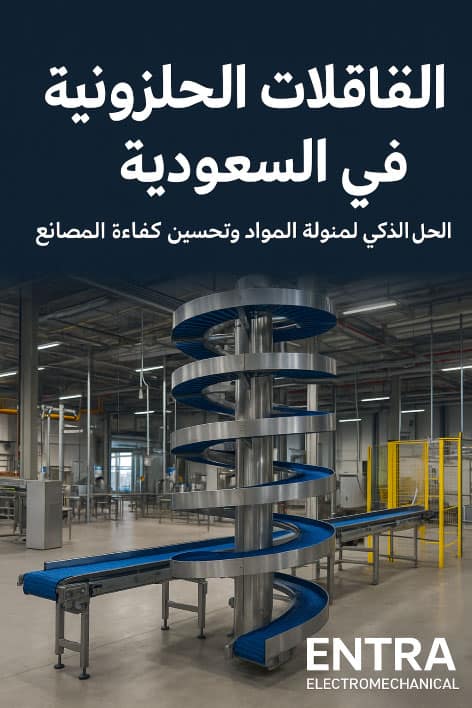

🔹 Overhead Conveyors

Used in clean production environments or for maximizing space.

Advantages:

-

Frees floor space

-

Great for paint lines, assembly lines

-

Can follow complex routing

4. Automated Conveyor Systems: A Game Changer

Keyword Target: Automated conveyor systems

Automation is a top priority for operations managers in 2025. Automated conveyor systems include smart sensors, PLCs, and sometimes even robotic arms to optimize movement and monitor system health in real-time.

Features:

-

Automatic speed adjustment

-

AI-based routing

-

Integration with WMS & ERP

-

Preventive maintenance alerts

Benefits:

-

Lower labor dependency

-

Higher throughput

-

Greater system visibility

5. Key Benefits of Advanced Conveyor Systems

Implementing advanced conveyor systems provides:

| Benefit | Description |

|---|---|

| ✅ Increased Productivity | Faster product movement and reduced manual labor |

| ✅ Lower Operational Costs | Reduced labor and fewer production stoppages |

| ✅ Enhanced Safety | Less manual material handling |

| ✅ Data-Driven Control | Integrated sensors track performance |

| ✅ Scalability | Easily adapted for future growth |

With automation and modularity, today’s conveyor systems can scale with your business.

6. Factors to Consider Before Choosing a Conveyor System

Choosing the right system goes beyond price—here’s what procurement teams must evaluate:

-

Material type: Are you moving boxes, powder, or metal parts?

-

Load weight: Helps determine frame and motor specs.

-

Environment: Humid, food-grade, or explosive zones?

-

Layout complexity: Straight-line, incline, multi-level?

-

Speed requirements: Pieces per hour (PPH) targets.

-

Integration needs: ERP, barcode scanners, robotics?

Always consult a conveyor specialist to create a tailored solution.

7. Industry-Specific Conveyor Use Cases

Let’s look at how different industries leverage conveyor systems:

🏭 Manufacturing

-

JIT part delivery

-

Assembly line synchronization

🚚 Logistics & Warehousing

-

Sorting parcels for last-mile delivery

-

Real-time tracking with smart conveyors

🍪 Food & Beverage

-

Hygienic belt conveyors

-

Clean-in-place systems

🚗 Automotive

-

Chain conveyors for engine blocks

-

Overhead systems for doors & panels

Each use case demands specific features, such as temperature resistance, load capacity, and cleaning capabilities.

8. Conveyor Accessories That Boost Performance

Keyword Target: Conveyor accessories

Accessories transform a basic system into a high-performance one:

| Accessory | Function |

|---|---|

| 📦 Diverters & Merges | Route packages dynamically |

| 🔄 Turntables | Redirect flow direction |

| 🧠 Sensors | Enable smart automation |

| 🔧 Safety Rails | Prevent products from falling |

| 🔌 Speed Controllers | Adjust pace as needed |

Upgrading with accessories boosts flexibility, safety, and automation potential.

9. Conveyor System Case Study: Lean Manufacturing Integration

🏢 Company: Alnasr Chemicals – Giza, Egypt

Challenge: High downtime during material transfers

Solution: Integrated roller + belt conveyor system with automated PLC controls

Results:

-

Downtime reduced by 40%

-

Labor cost cut by 30%

-

ROI achieved in 18 months

This real-world example demonstrates the power of customized material handling solutions.

10. Future Trends in Conveyor System Design

As Industry 4.0 evolves, conveyor technology is advancing:

-

IoT Integration: Real-time data via smart sensors

-

AI-Driven Routing: Dynamic traffic optimization

-

Modular Design: Easy upgrades and retrofits

-

Eco-Friendly Belts: Recyclable materials and energy-efficient motors

-

Robotics Collaboration: Seamless robot-conveyor interaction

Smart factories are investing heavily in these technologies to remain competitive in 2025 and beyond.

11. Conclusion

If you’re aiming to improve production speed, reduce human error, and optimize operations, investing in the right conveyor system is a strategic decision.

From belt conveyors to automated conveyor systems, manufacturers have more choices than ever to meet unique workflow demands.

By understanding your material type, production needs, and long-term goals, you can build a conveyor system that scales with your business and delivers consistent ROI.

12. Frequently Asked Questions (FAQs)

Q1: What’s the most cost-effective type of conveyor system?

A: For basic material movement, gravity roller conveyors are the most budget-friendly. For versatility and automation, belt conveyors are a solid mid-range option.

Q2: Can I retrofit accessories into my old conveyor system?

A: Yes. Most conveyor accessories such as sensors and guides can be added later to enhance performance.

Q3: How long does a modern conveyor system last?

A: With proper maintenance, modern systems last 10–15 years, and automated models can provide real-time alerts for preventative servicing.

Q4: Are conveyor systems suitable for small factories?

A: Absolutely. Modular conveyor systems can be scaled to fit small spaces and grow as your operations expand.