Top Conveyor Systems for Streamlining Factory Workflows in 2025

July 22, 2025

A Complete Guide to Industrial Conveyors: Types, Uses, and Benefits

July 24, 2025Table of Contents

-

Introduction

-

What Is Material Handling Equipment?

-

Types of Material Handling Equipment Used in Manufacturing

-

Conveyors

-

Lifting Equipment

-

Storage Systems

-

Industrial Trucks

-

-

The Link Between Material Handling and Plant Efficiency

-

Benefits of Investing in the Right Equipment

-

Common Inefficiencies Caused by Poor Handling Systems

-

Key Selection Criteria for Efficient Material Handling

-

How Material Handling Supports Lean Manufacturing

-

Real-World Application: Efficiency Boost in a Mid-Sized Factory

-

Maintenance and Lifecycle Optimization

-

Future Trends in Material Handling Equipment

-

Conclusion

-

FAQs

1. Introduction

As global competition increases, manufacturers are under pressure to maximize productivity while cutting costs. One of the most overlooked ways to achieve this is through effective material handling equipment.

From automated conveyors to ergonomic lifting systems, having the right tools in place directly impacts plant efficiency, safety, and output quality. This guide explores how modern handling systems create smarter, more efficient production lines.

2. What Is Material Handling Equipment?

Material handling equipment refers to the mechanical systems and tools used to move, protect, store, and control materials throughout the manufacturing process.

This includes:

-

Raw material intake

-

In-process handling

-

Storage

-

Packaging

-

Distribution

Efficient handling reduces manual intervention, accelerates production time, and minimizes material damage or loss.

3. Types of Material Handling Equipment Used in Manufacturing

Let’s break down the major categories used in industrial settings:

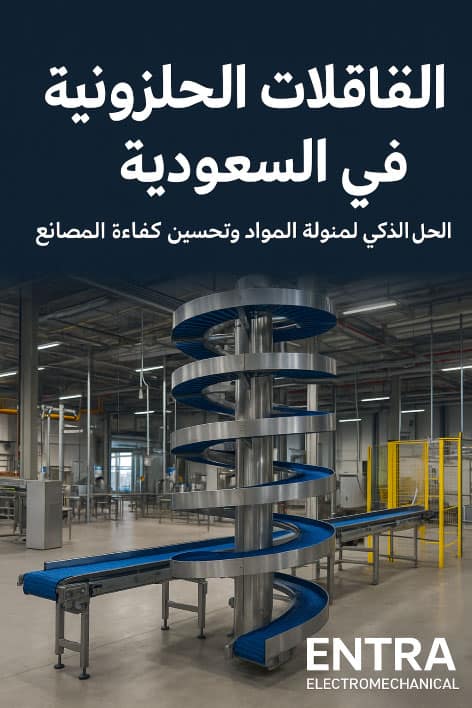

🔹 Conveyor Systems

Related Keyword: Conveyor systems

Automated conveyors move materials efficiently across production zones. Types include belt conveyors, pallet handling conveyors, and automated conveyor systems.

Use Case: Assembly lines, packaging stations, distribution hubs.

🔹 Lifting Equipment

Includes hoists, cranes, and robotic arms.

Function: Move heavy items safely and reduce worker strain.

Industries: Automotive, aerospace, heavy machinery.

🔹 Storage Systems

Racking, shelving, and automated storage and retrieval systems (ASRS) fall under this category.

Goal: Optimize warehouse space and improve material access speed.

🔹 Industrial Trucks

Forklifts, pallet jacks, and automated guided vehicles (AGVs) are used for moving materials within a facility.

4. The Link Between Material Handling and Plant Efficiency

Here’s how material handling equipment directly improves plant operations:

| Efficiency Factor | Impact of Good Material Handling |

|---|---|

| ✅ Time | Shorter transit and loading times |

| ✅ Labor | Less manual work, fewer injuries |

| ✅ Space | Better layout utilization |

| ✅ Inventory | Fewer losses and damages |

| ✅ Production Flow | Smoother process with less downtime |

Automated handling systems cut non-value-added time and enable consistent throughput.

5. Benefits of Investing in the Right Equipment

If you’re a plant manager or procurement officer, here’s why investing in the right material handling equipment matters:

✅ Increased Output

Faster material movement = higher production rates.

✅ Reduced Downtime

Fewer equipment jams and less reliance on human handling.

✅ Improved Safety

Minimized risk of injuries from lifting, tripping, or product drops.

✅ Better Product Quality

Reduces damage from poor handling or storage.

✅ Cost Savings

Lower labor costs, maintenance, and operational delays.

6. Common Inefficiencies Caused by Poor Handling Systems

Here are the signs that your current system is holding you back:

-

Frequent machine stops due to material unavailability

-

Long worker transit paths

-

High accident or injury rates

-

Overstocking or underutilization of space

-

Missed production deadlines

These inefficiencies lead to higher operating costs and customer dissatisfaction.

7. Key Selection Criteria for Efficient Material Handling

Not all equipment is created equal. Your selection should be based on:

| Factor | Why It Matters |

|---|---|

| Load Type | Size, shape, fragility of materials |

| Volume | Daily throughput affects design and specs |

| Space | Equipment must fit your facility layout |

| Process Integration | Must work with existing systems like ERP |

| Safety Standards | Must meet local and international guidelines |

| Flexibility | Modularity allows future expansion or reconfiguration |

Working with experienced providers helps tailor the equipment to your specific needs.

8. How Material Handling Supports Lean Manufacturing

Lean principles aim to eliminate waste—material handling systems are core to this.

Here’s how:

| Lean Waste Type | Solution via Handling Equipment |

|---|---|

| Transport Waste | Use conveyors for flow efficiency |

| Waiting Time | Automate loading/unloading |

| Motion Waste | Reduce manual travel distances |

| Inventory Waste | ASRS systems manage space |

| Defects | Gentle handling reduces breakage |

By aligning handling systems with Lean, you improve efficiency without major capital investment.

9. Real-World Application: Efficiency Boost in a Mid-Sized Factory

🏢 Client: Local FMCG Manufacturer – 2024 Upgrade

Challenge: Manual movement of heavy boxes caused injuries and process delays.

Solution: Introduced belt conveyors, ergonomic lifts, and automated storage.

Results:

-

50% faster material flow

-

35% reduction in labor cost

-

70% fewer material damage reports

-

Payback period: 14 months

Insight: Even a modest investment in material handling equipment had massive ROI.

10. Maintenance and Lifecycle Optimization

To maximize ROI, focus on equipment maintenance and lifecycle planning:

🔧 Preventive Maintenance

Regular checks reduce breakdowns and costly downtime.

📊 Monitoring Tools

Modern systems provide performance data for predictive servicing.

🛠 Spare Parts Planning

Work with suppliers to ensure critical spares availability.

🔄 Upgradability

Choose systems that allow software and hardware expansion.

11. Future Trends in Material Handling Equipment

🔹 AI Integration

-

Smart sensors analyze movement patterns

-

Predict bottlenecks and automate rerouting

🔹 Collaborative Robots (Cobots)

-

Work alongside humans in hybrid workflows

-

Ideal for packing, sorting, and loading

🔹 IoT-Enabled Equipment

-

Real-time tracking of load movement and machine health

🔹 Green Handling Systems

-

Energy-efficient motors

-

Recyclable conveyor belts

-

Compact systems for better space use

Future factories will rely on these innovations to remain competitive and sustainable.

12. Conclusion

Whether you run a small plant or a large industrial facility, upgrading your material handling equipment is one of the most effective ways to boost efficiency, safety, and profitability.

From conveyors to robotic lifts, every piece of equipment should serve your goal: smarter, faster, leaner production.

Investing now not only helps solve today’s problems—it future-proofs your operations.

13. Frequently Asked Questions (FAQs)

Q1: What is the ROI of upgrading material handling equipment?

A: Most upgrades pay for themselves within 12–24 months via increased throughput, reduced labor, and lower downtime.

Q2: How do I know which type of equipment I need?

A: Start with a process audit. Consider materials, space, volume, and integration with your current system.

Q3: Can handling equipment be integrated with my ERP or MES system?

A: Yes, many systems support API or PLC-based integration for real-time monitoring and control.

Q4: What is the most common mistake in material handling design?

A: Designing around equipment instead of the workflow. Always focus on process first, then select equipment to match.